“InZanity” ’72 Datsun 240z

- The digitized version of what I have been seeing since the get go

- The goal was to modernize the 240z without losing its soul. I think mission accomplished

- look at the style lines, those are crisp and accurate

- fresh out of the booth, ready for color sanding and buff

- laying out ideas for some vinyl graphics. much tape was wasted, but I created a design that works from all angles and looks great

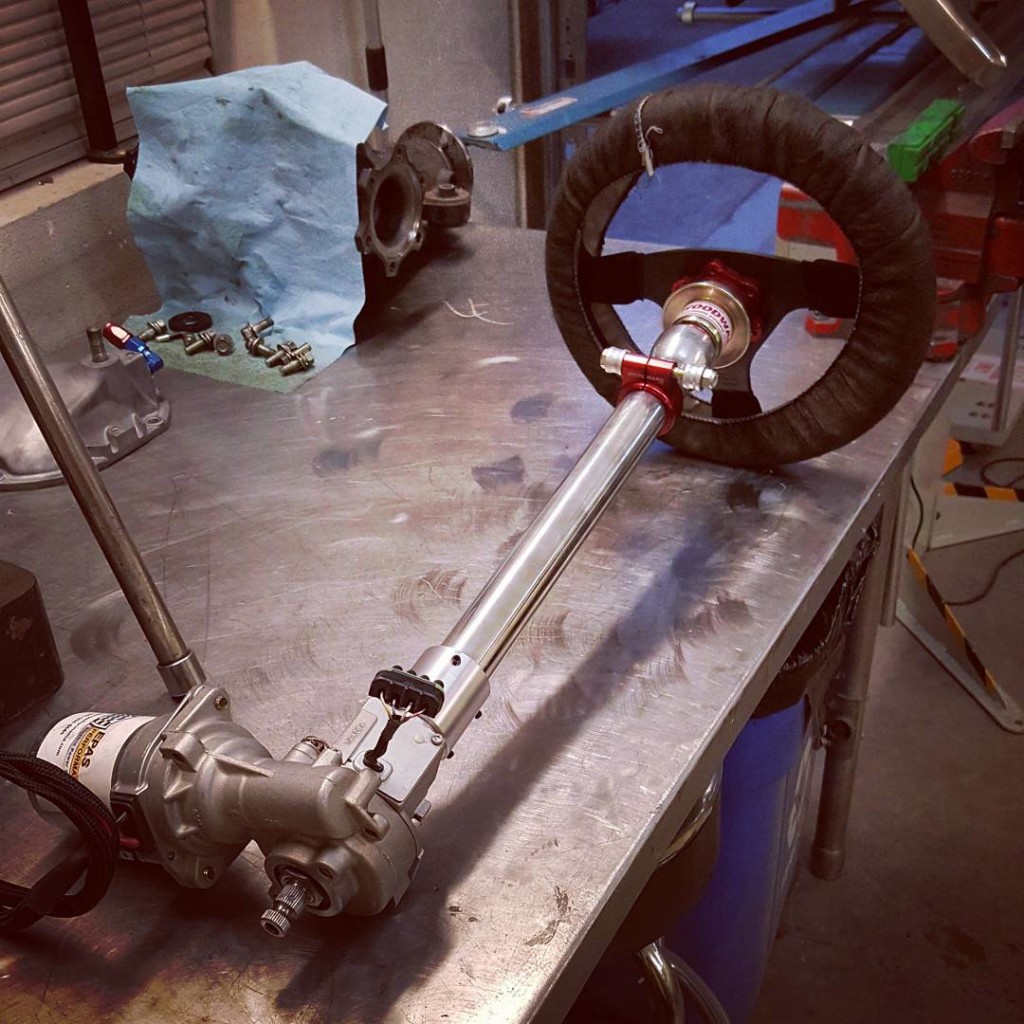

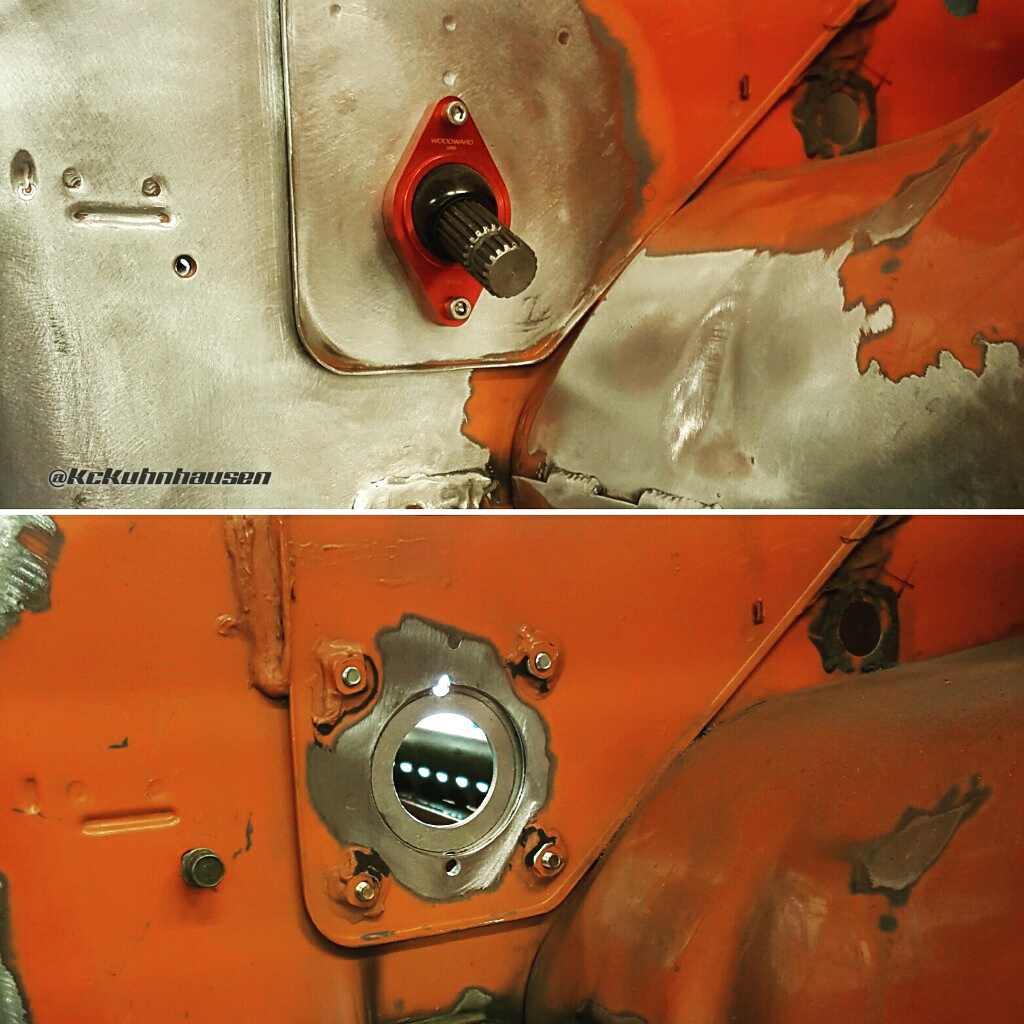

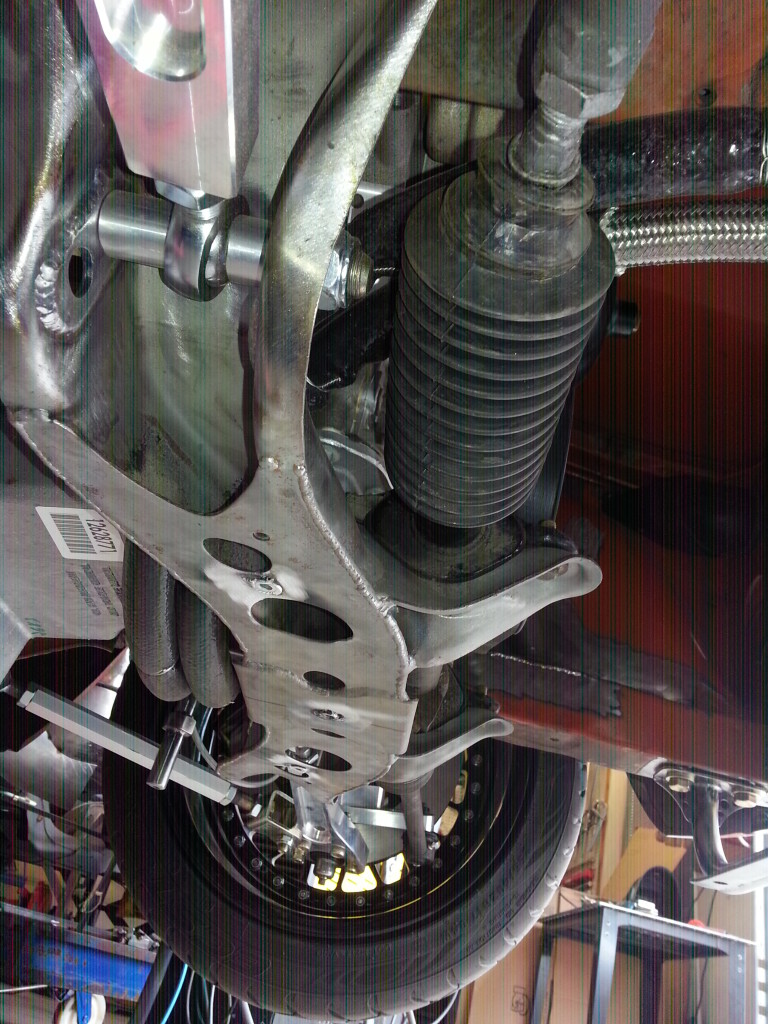

- modern electronic power steering with adjustable input… in a 72 240z

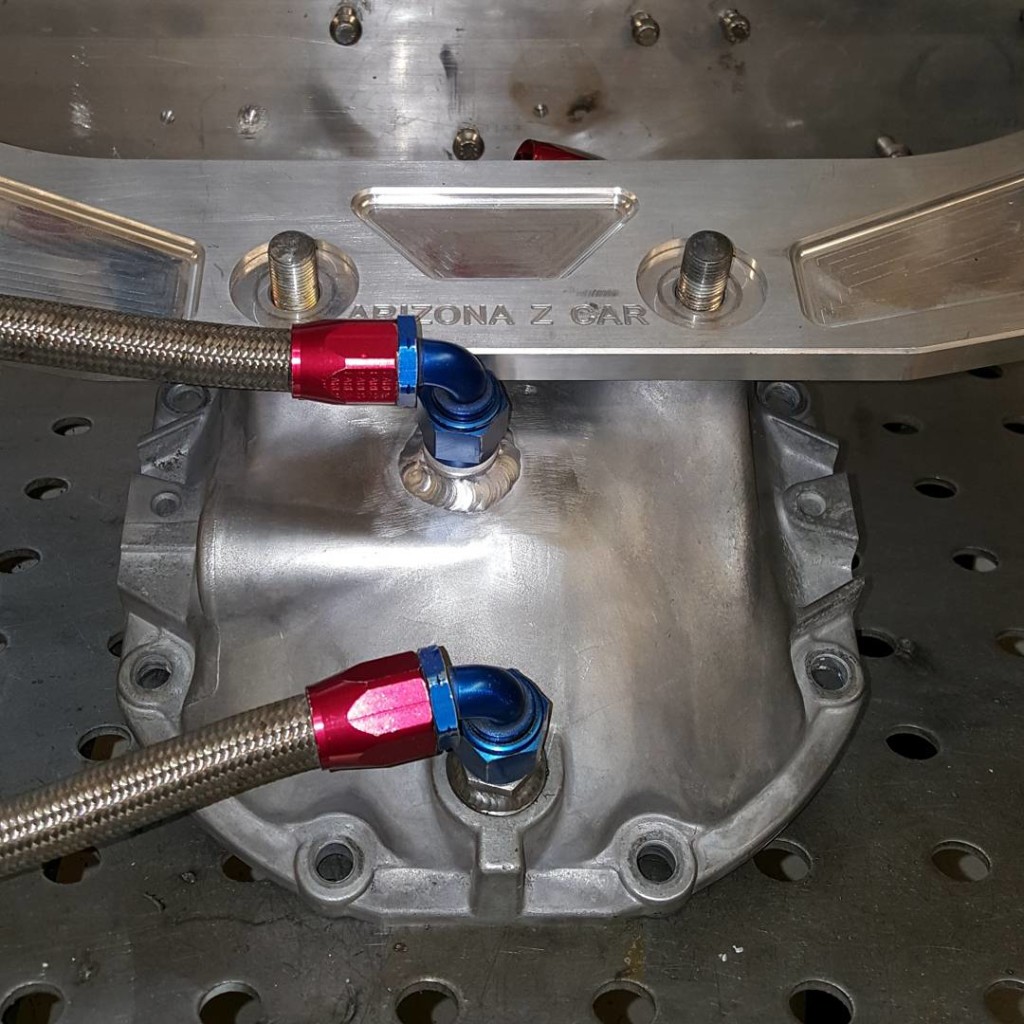

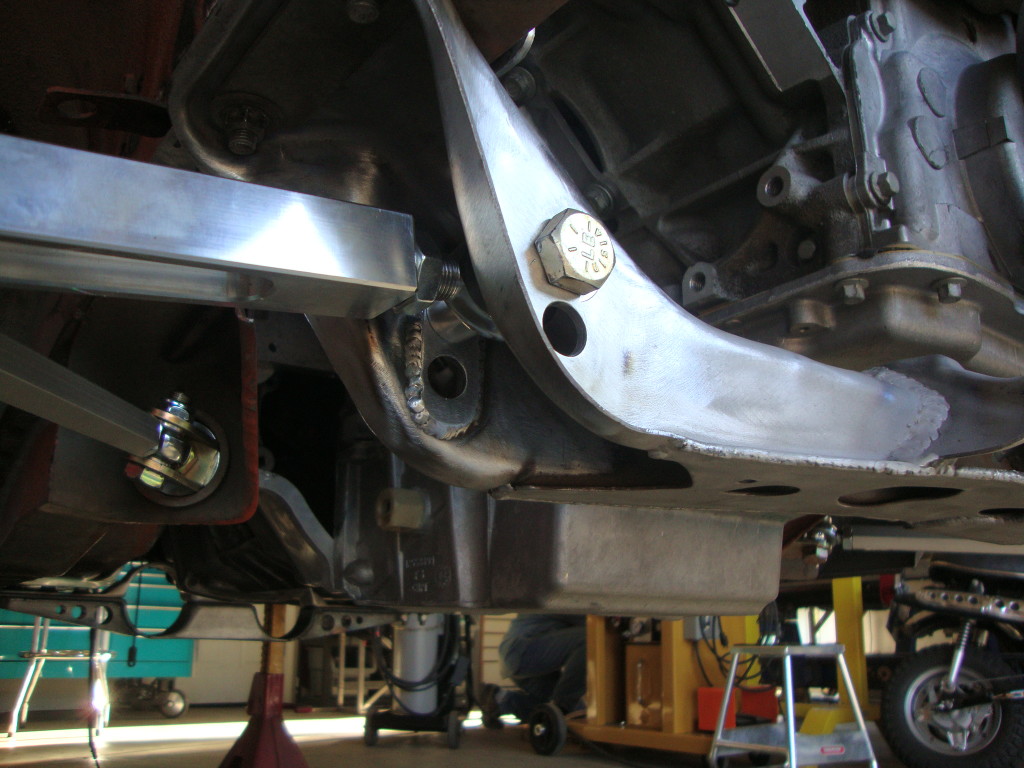

- the highlt modified rear differential cover.

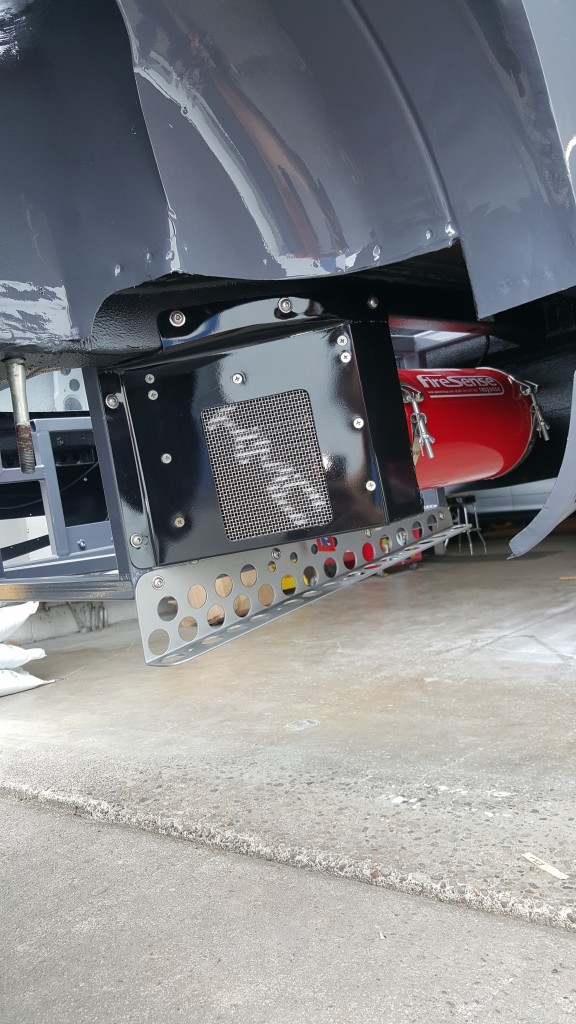

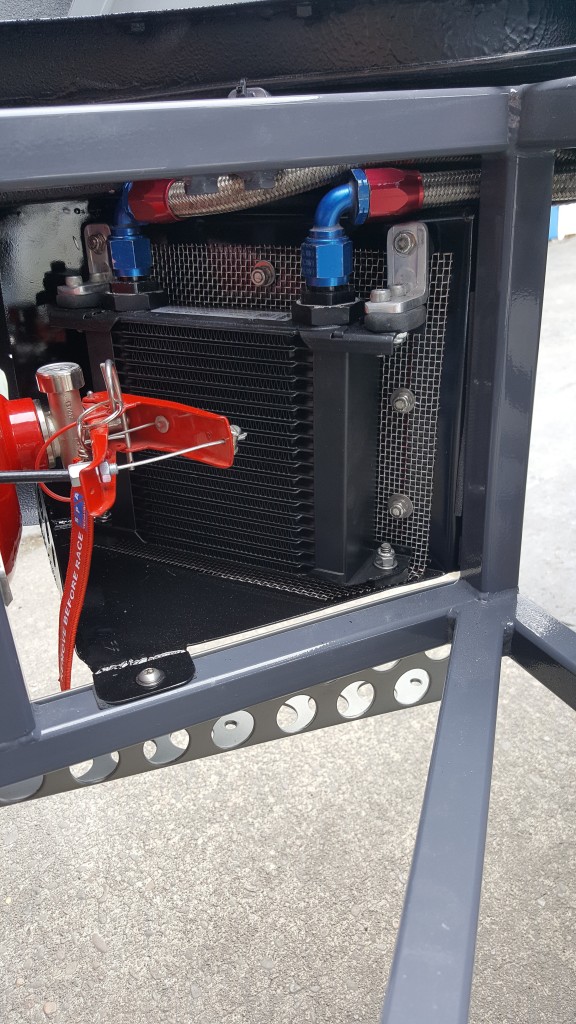

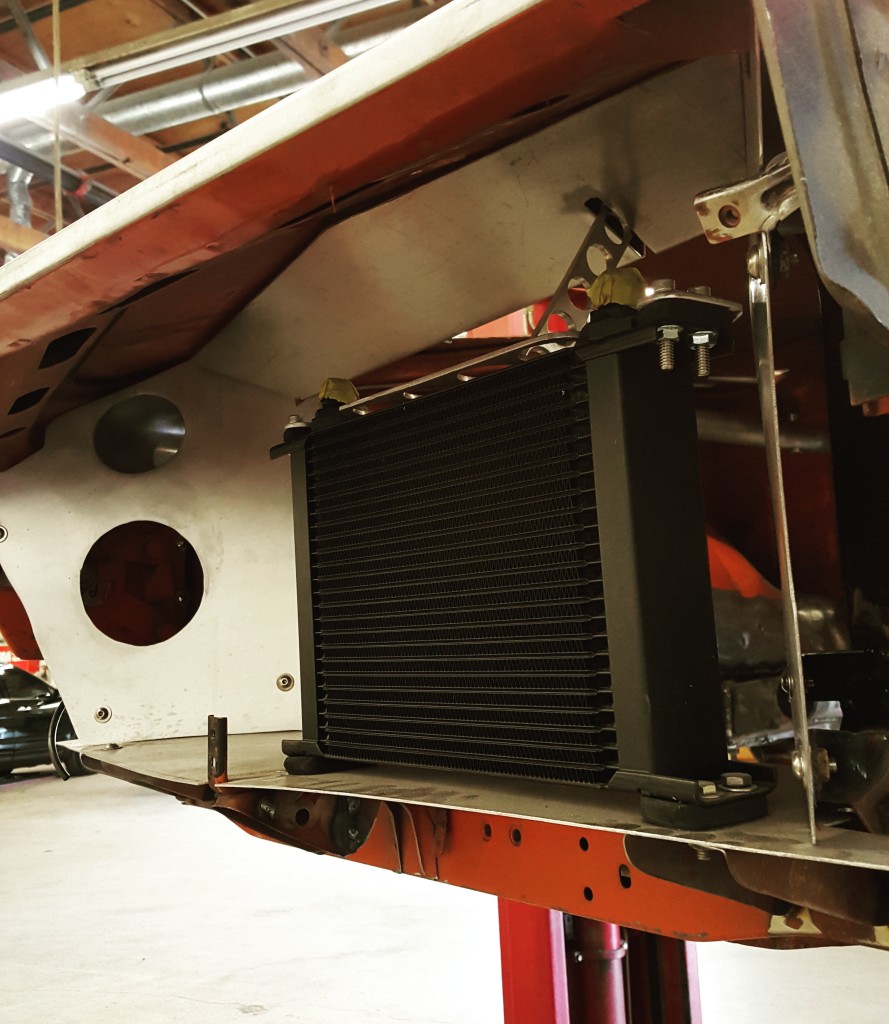

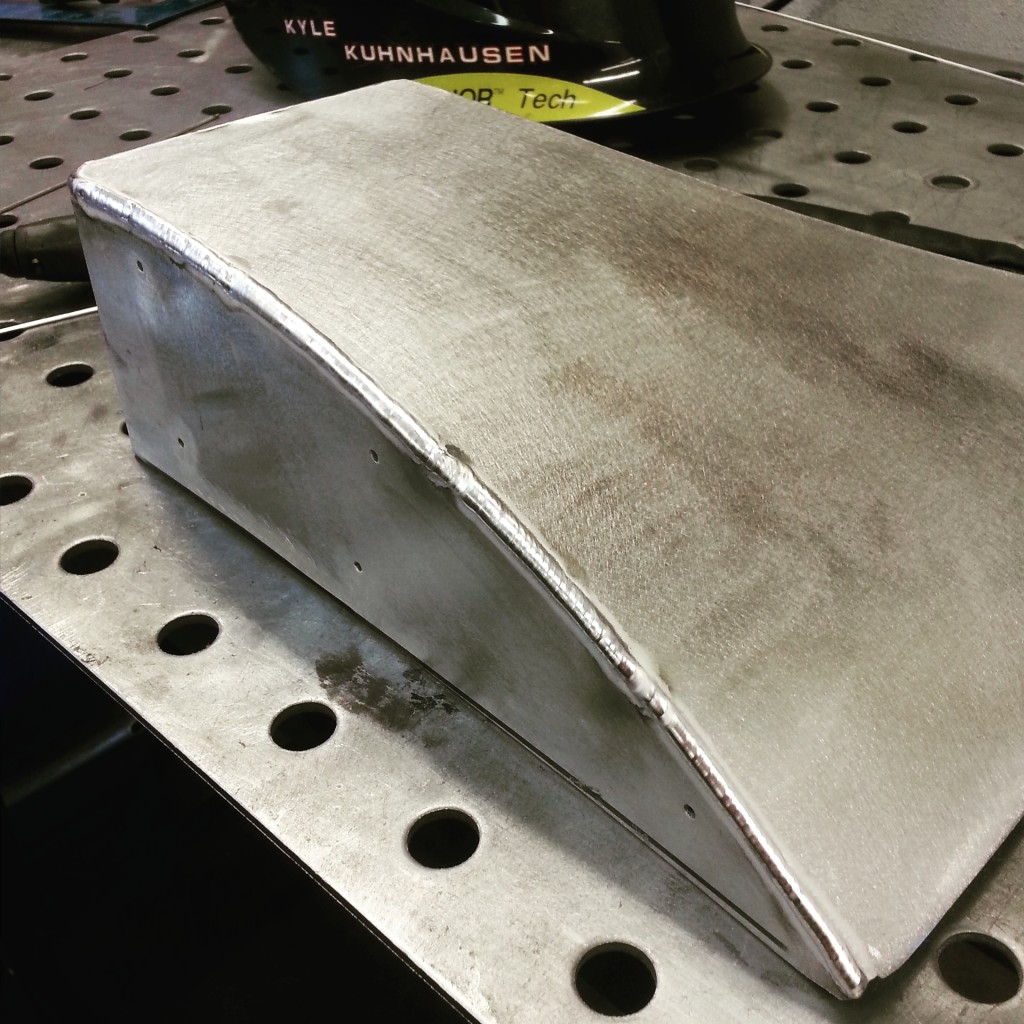

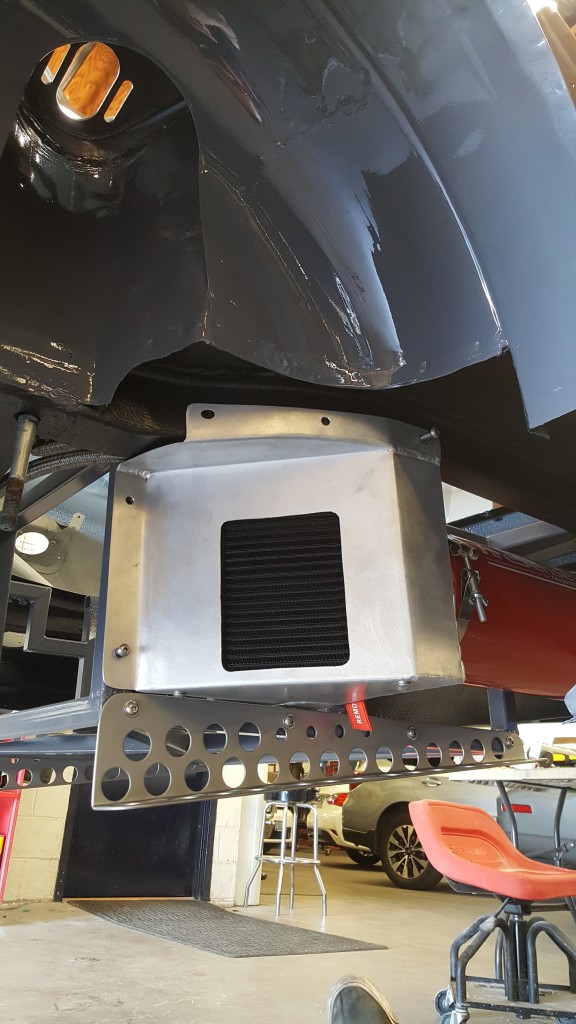

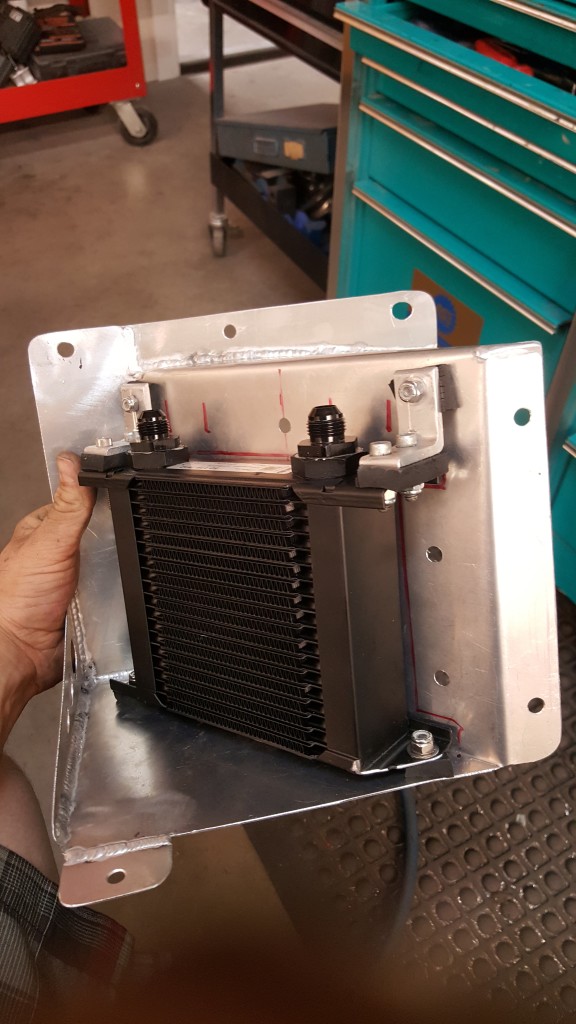

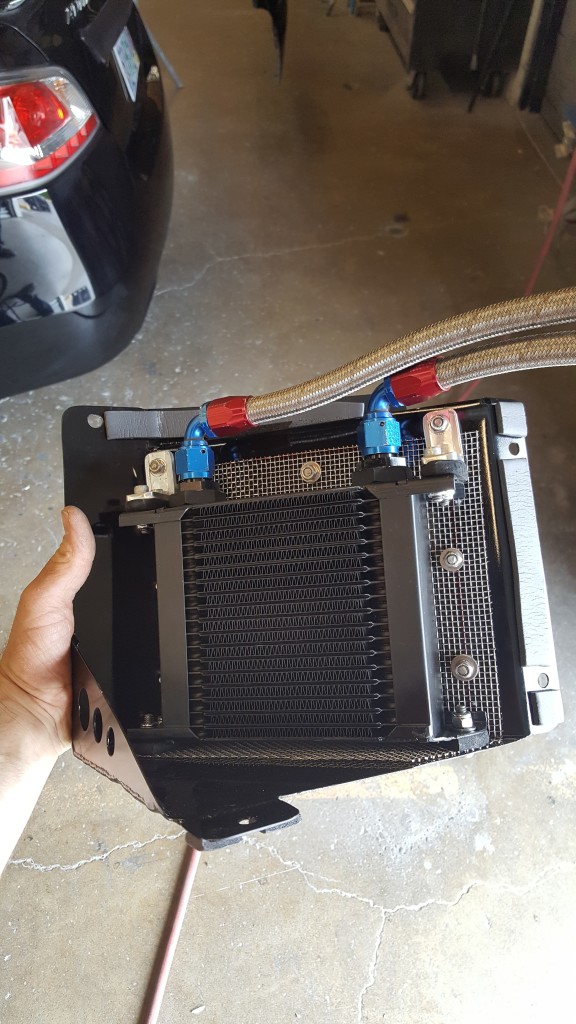

- one of my favorite pieces, this light gauge alloy shield hides the rear differential cooler behind the wheel

- no room to spare

- details you will see from outside the car

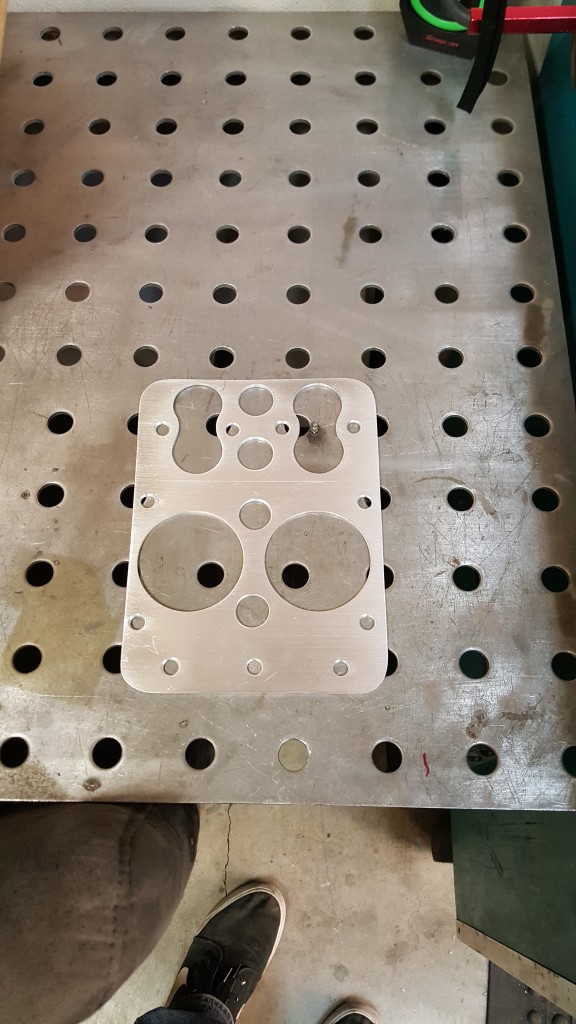

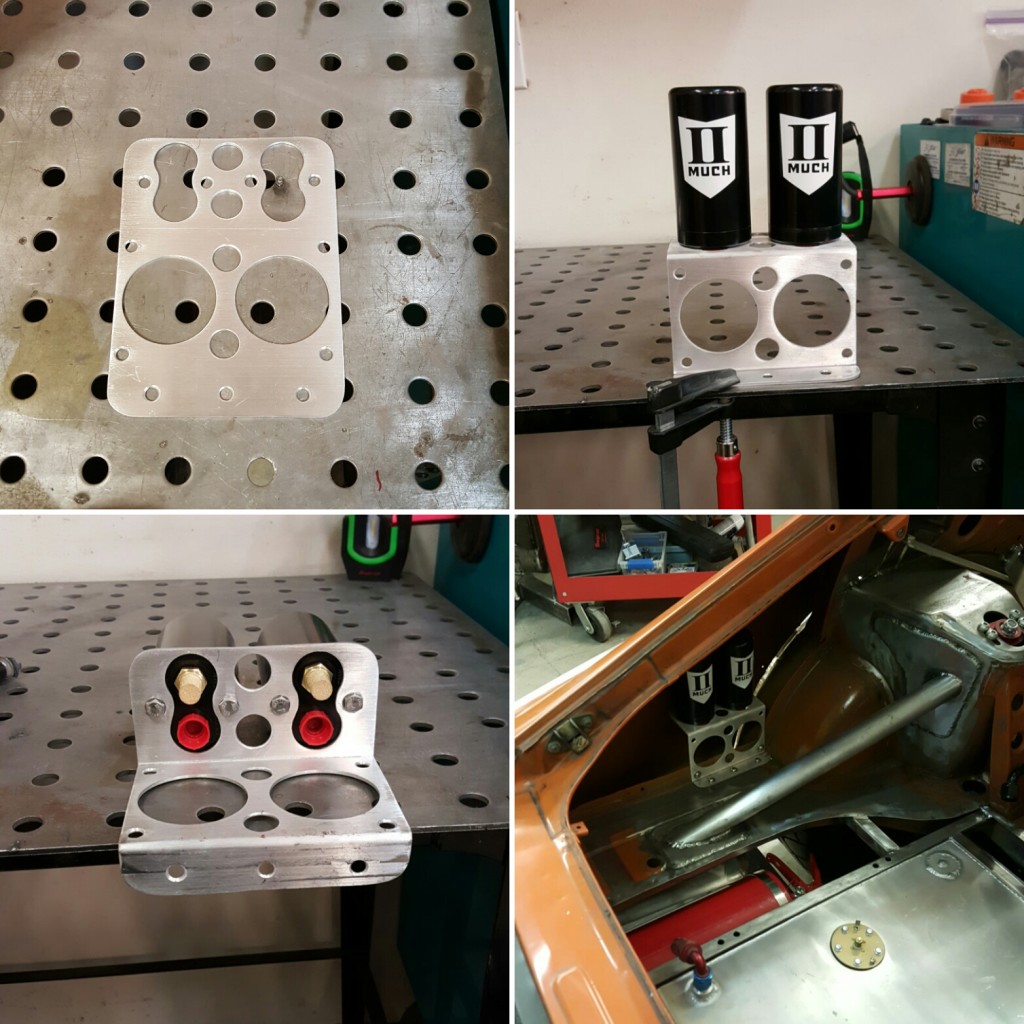

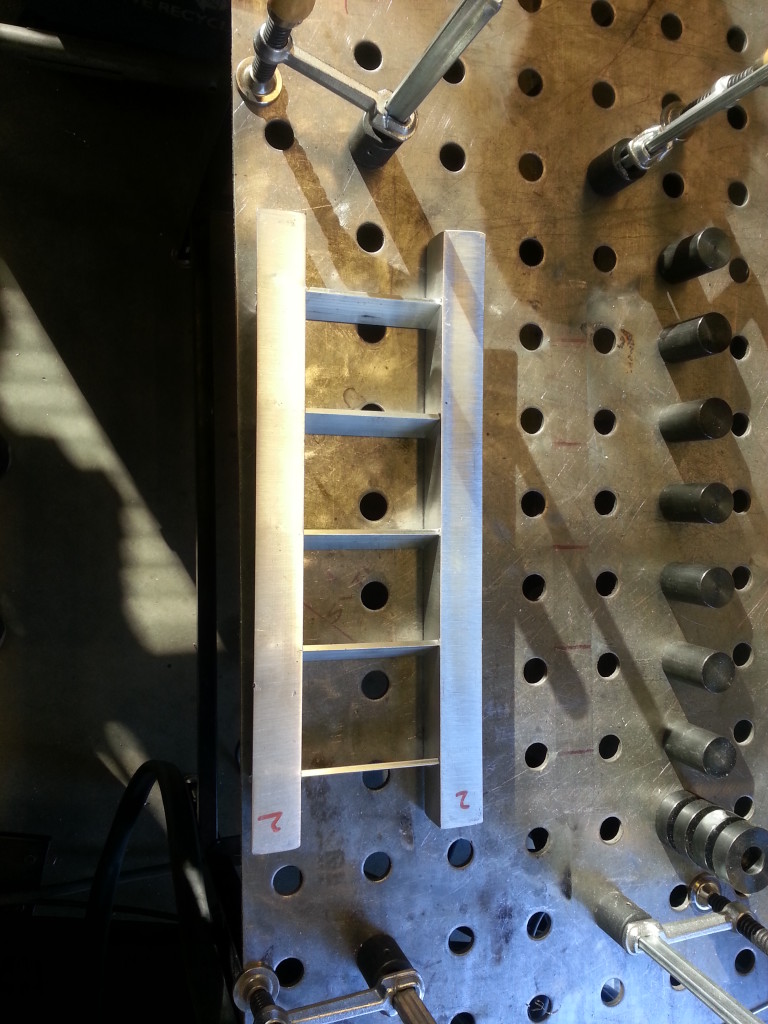

- I designed these custom cnc snout oilers to hugely upgrade the differential oiling system

- fresh powdercoated goodies ready for assembly

- One hell of a well executed design if you ask me

- my favorite color ever, it brings this chassis decades ahead, dare I say to modern times

- these colors should play very well together. A bit more interesting than plain satin black

- a taste of what is to come…

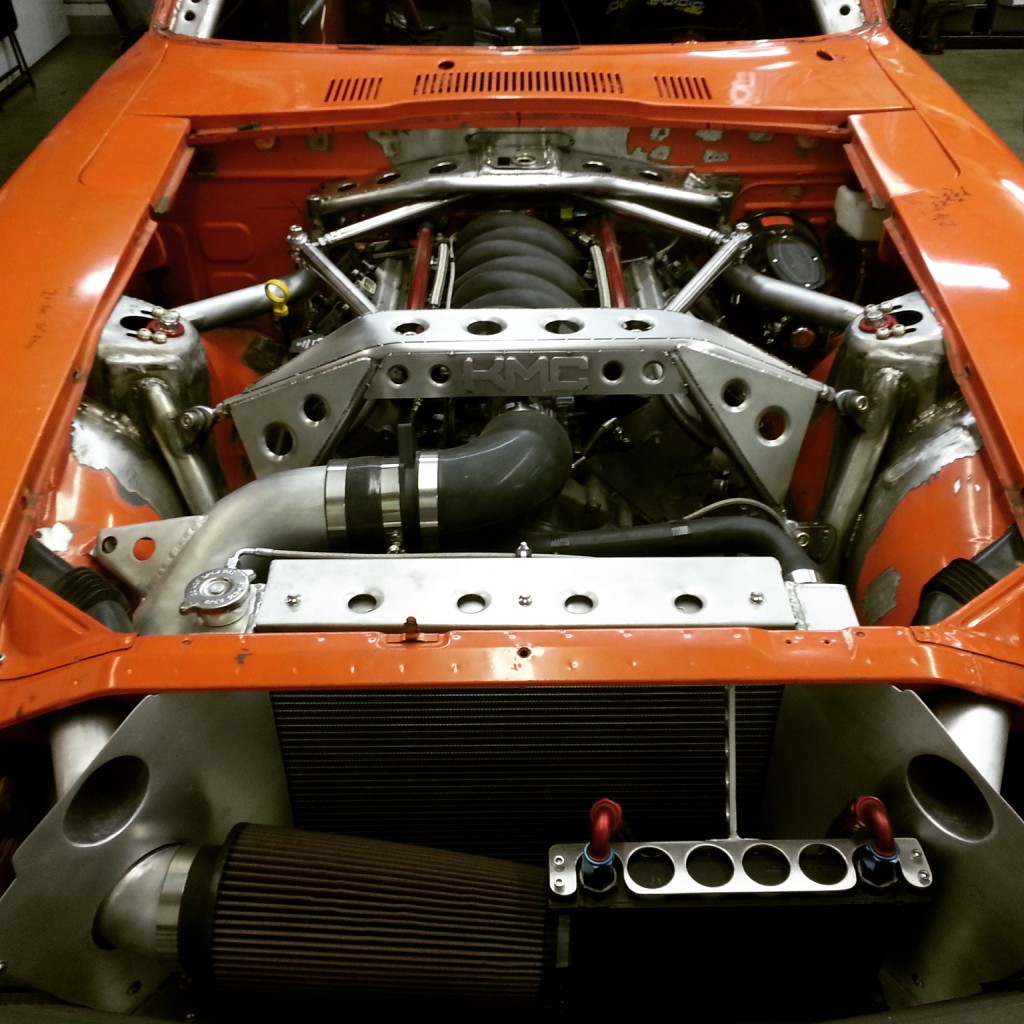

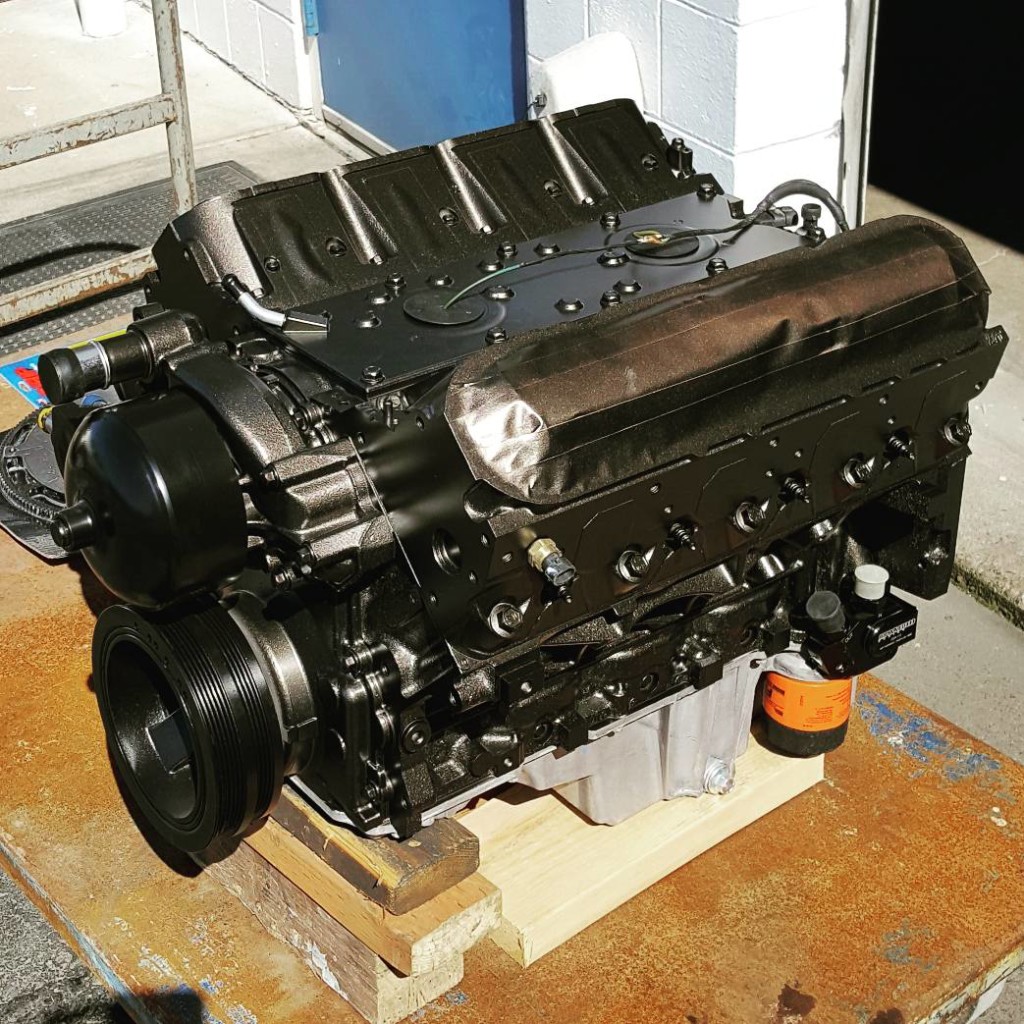

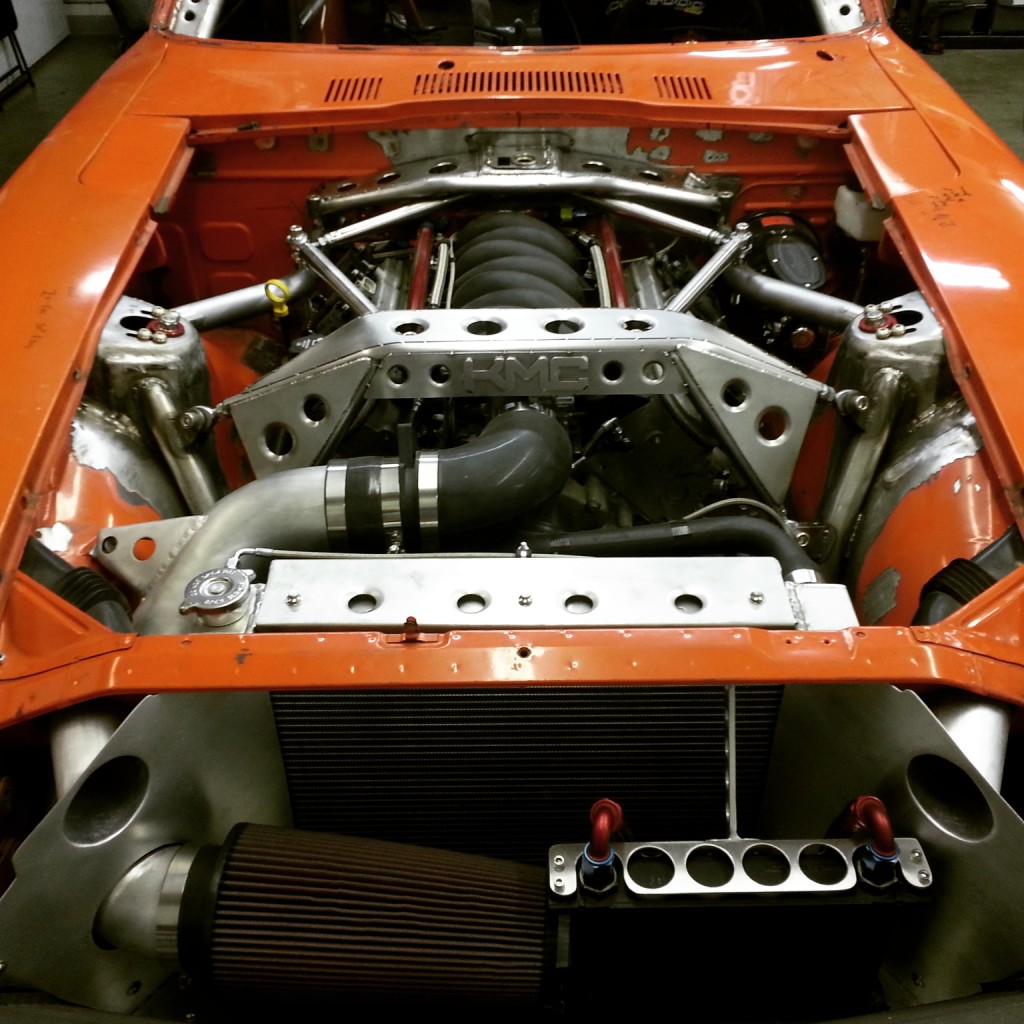

- I rolled the LS1 plant out into the sun for inspection

- A quick wet up shows how tight the style lines are after just 400 grit

- All those hours surely were worthwhile

- You see this in your rear view, its already too late

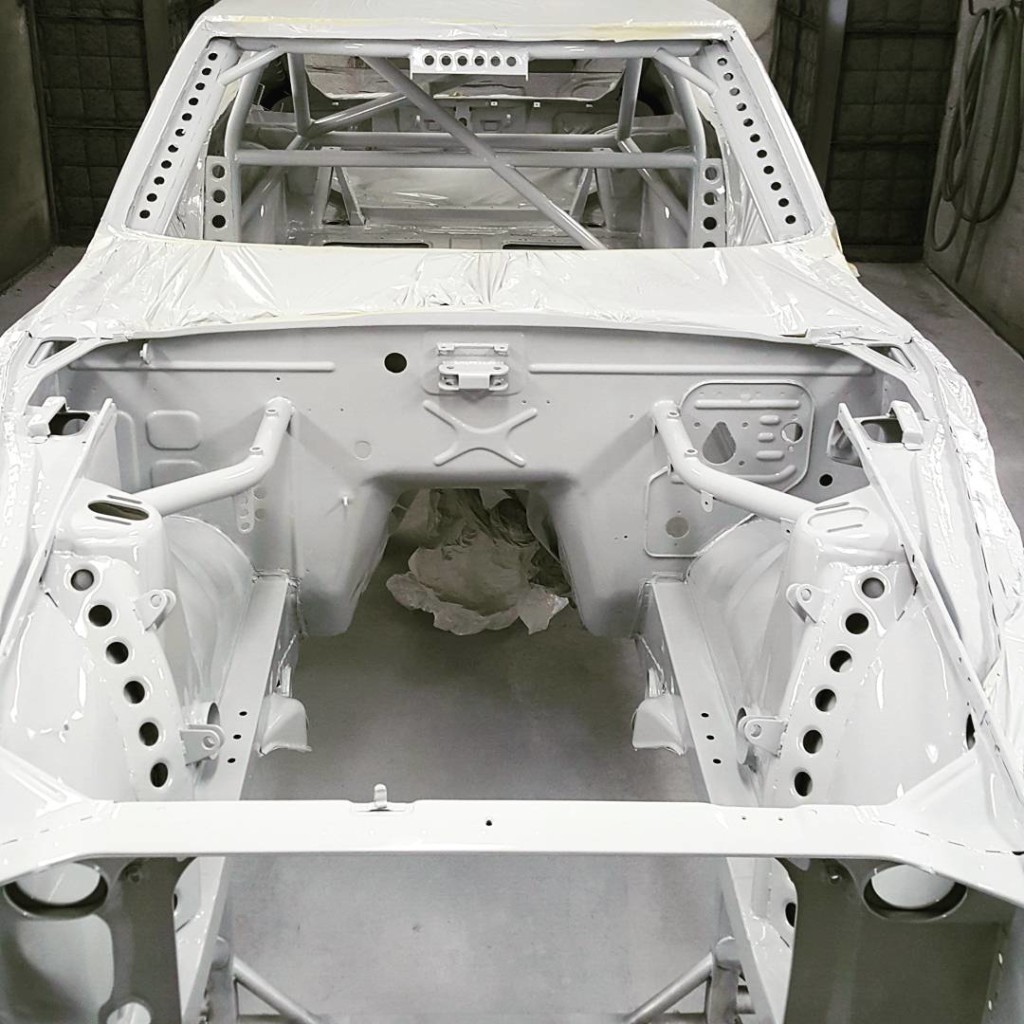

- I met the flared hole quota on this cage I do believe

- An interior that means business

- Finish welding the strut tower center support

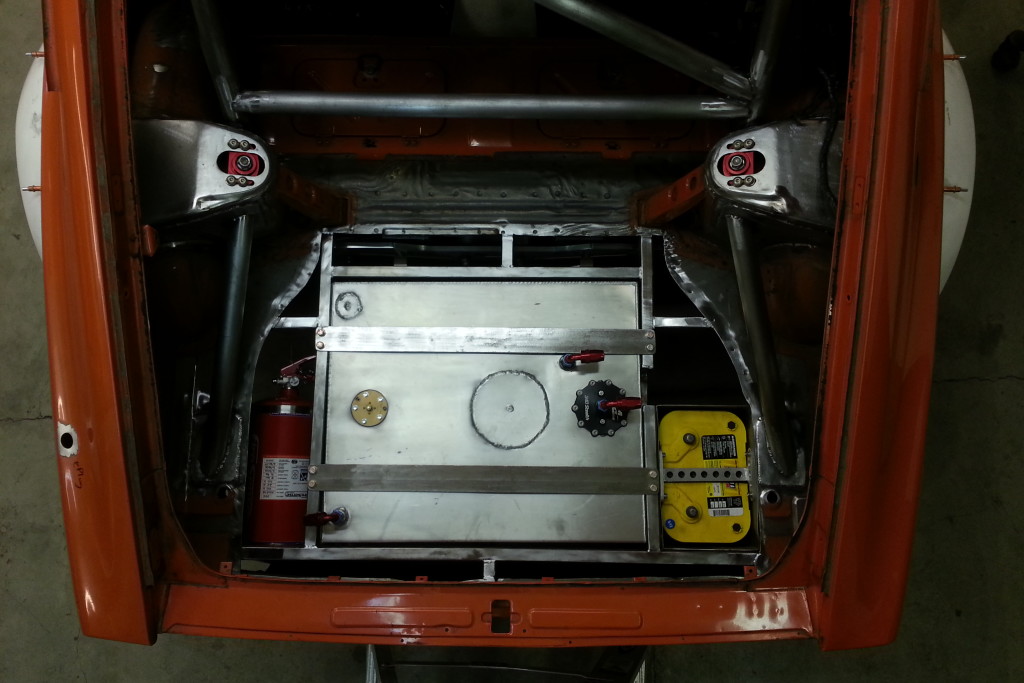

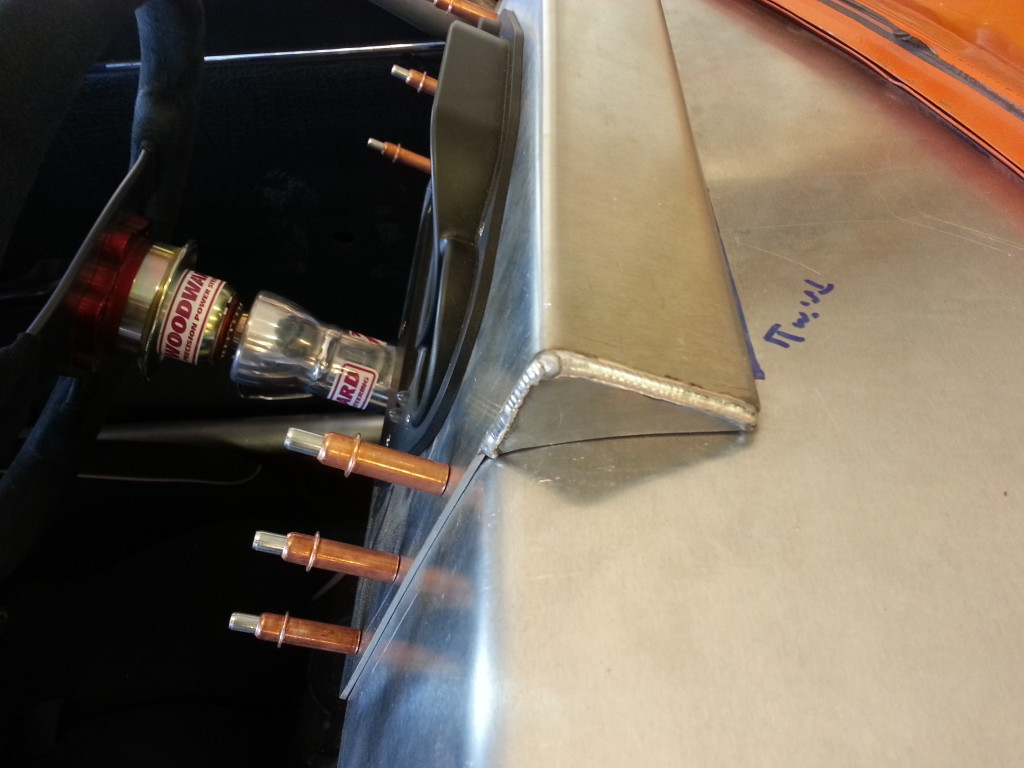

- A rear fuel cell firewall with a twist

- Presto, electric power steering on a Woodward column. All hidden under the dash.

- layers upon layers of custom fabrication and planning

- Unreal to see the exterior of the Z at this stage

- High performance can also be beautiful

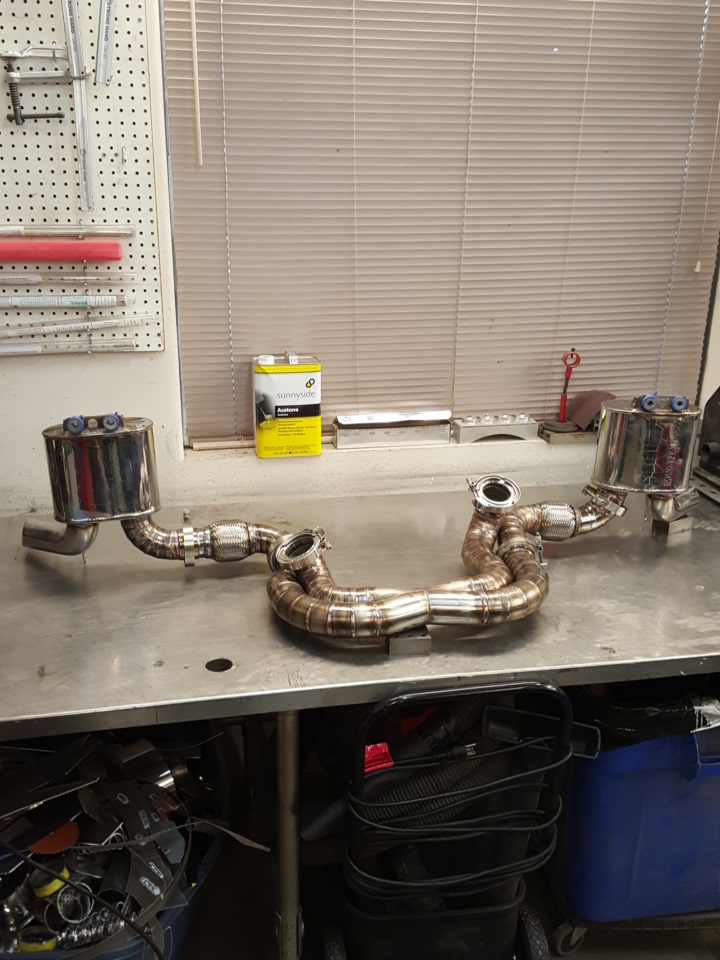

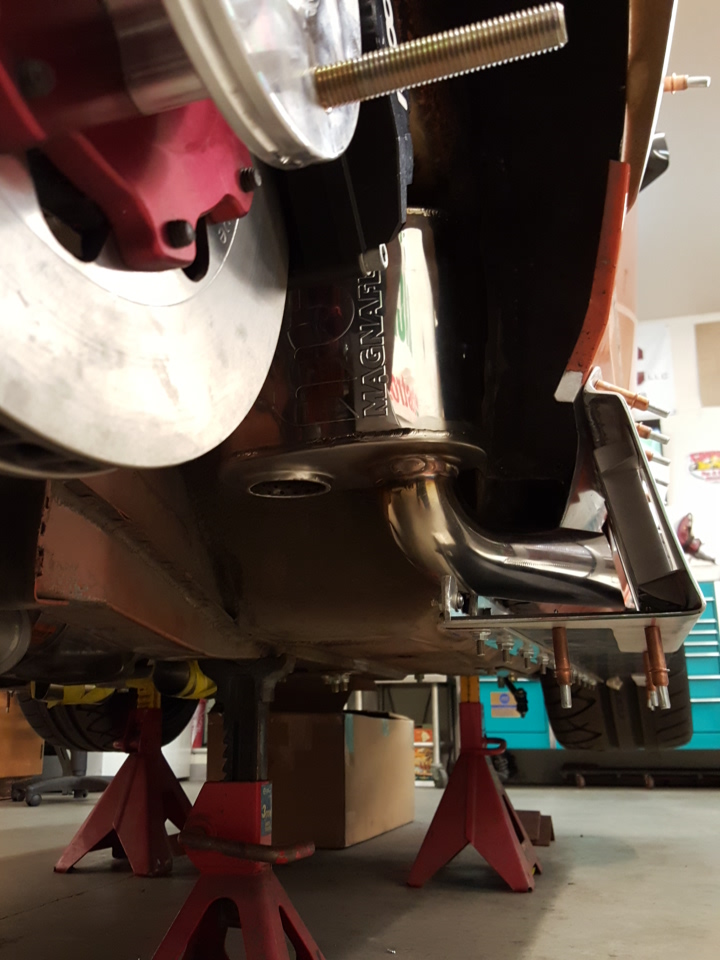

- 2.5″ Pie-cut stainless exhaust, back purged and tig welded to perfection

- yes, thats an exhaust pipe

- Applying a bedliner coating to the belly of the beast

- so many one-off hand made pieces. It brings me great joy to do this styff by hand

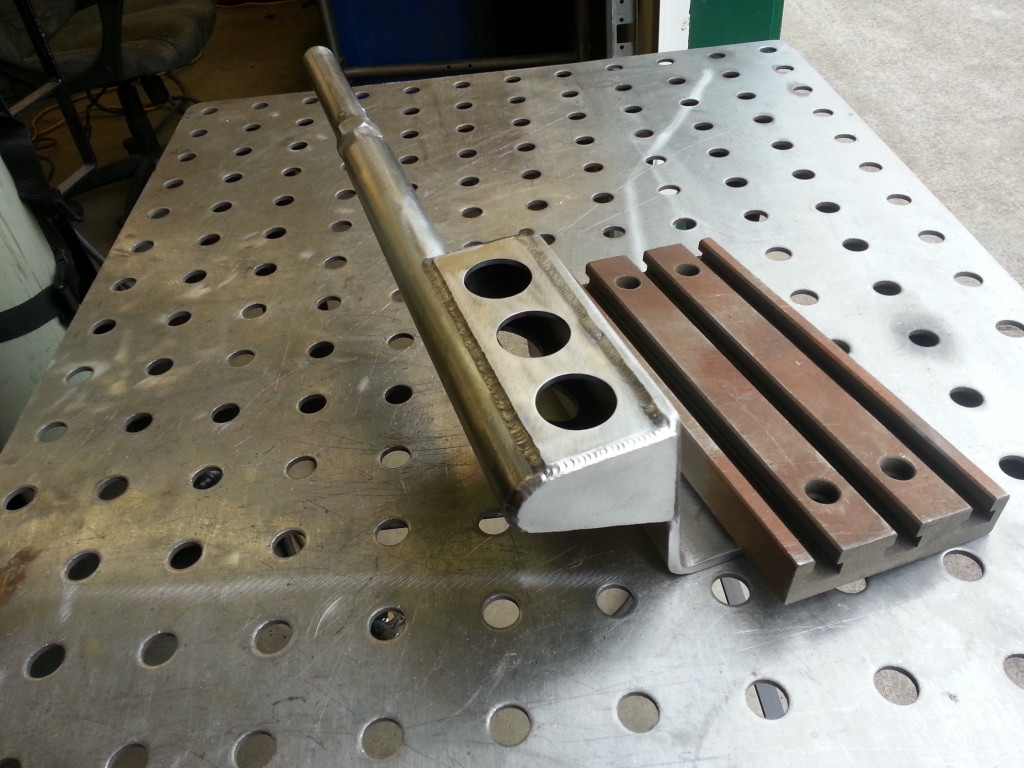

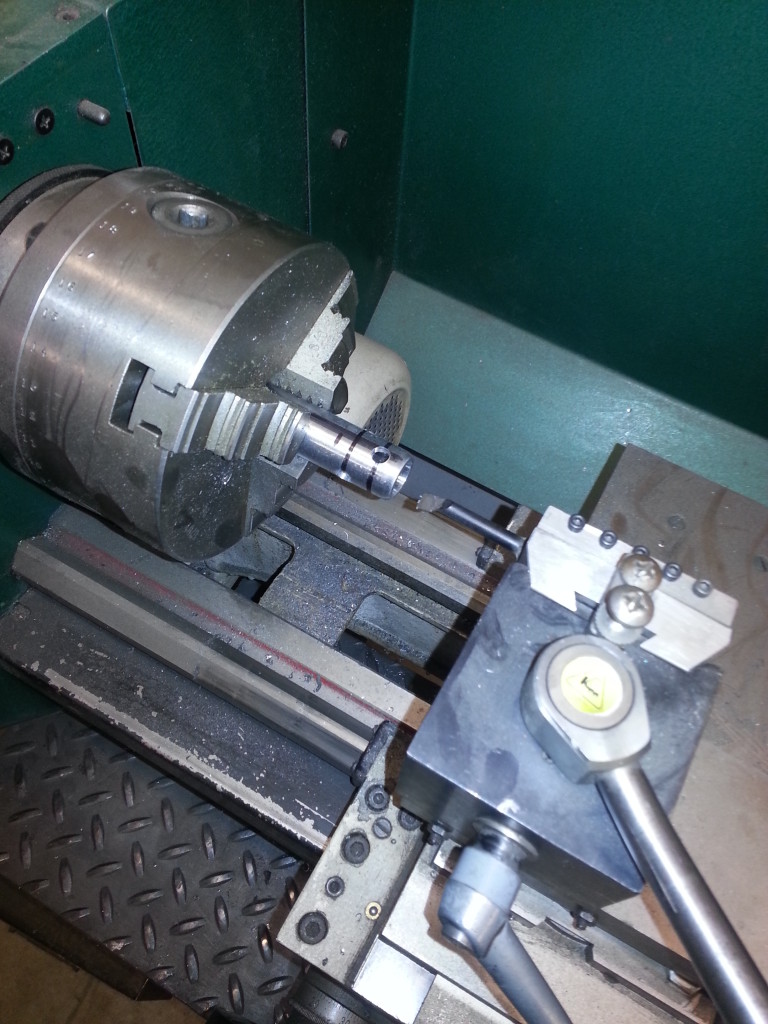

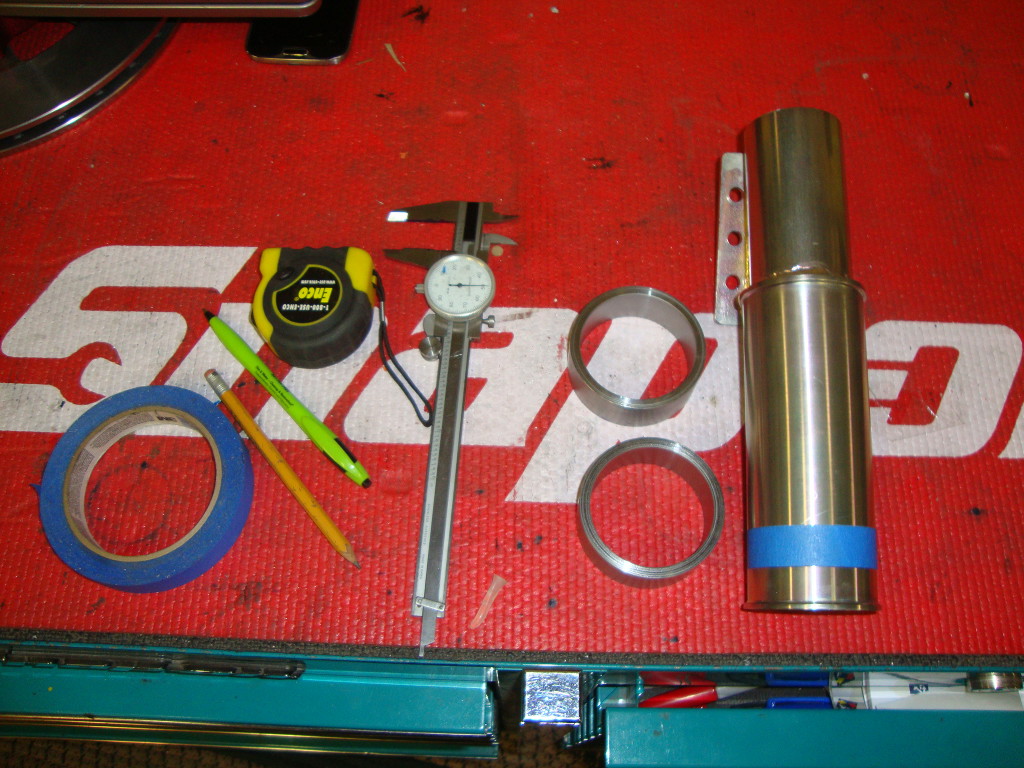

- precision sectioning the woodward steering column to accept the EPAS Power steering motor

- I machined a weld on shim to accept the O.D. of the EPAS shaft and the I.D. of the Woodward column

- Tig welding the shim to the motor

- seam sealing the bottom side seams

- LS1 looking fresh with the Holley coil on cover Valve covers and LS3 Coils

- Re-assembling the engine after paint

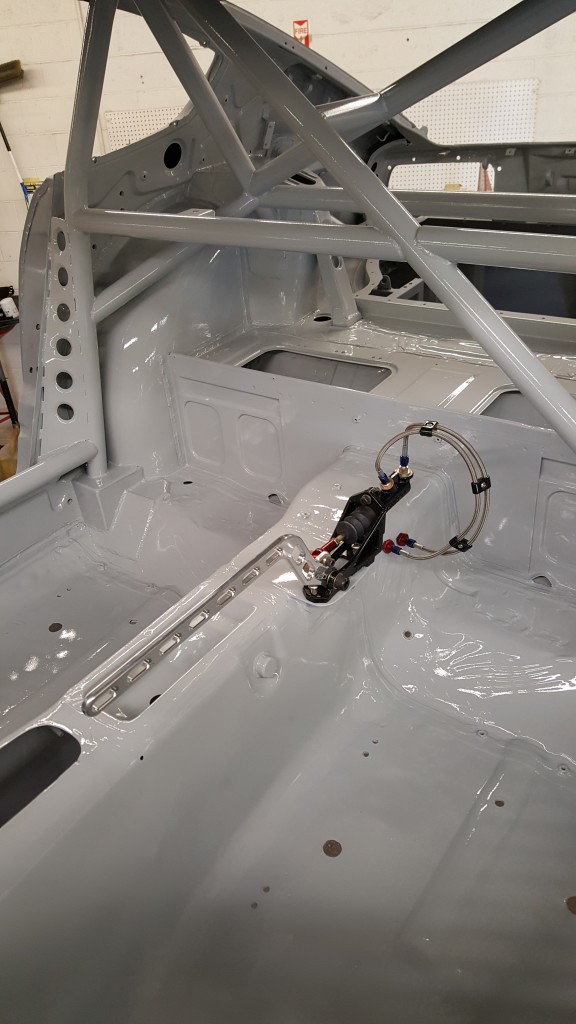

- Getting the interior and engine bay sprayed with a light gloss grey paint

- The cage work looks tidy with a uniform color

- Satin bronze for the LS1 Block and heads

- EPAS electric power steering should make driving this beast a bit more tamable

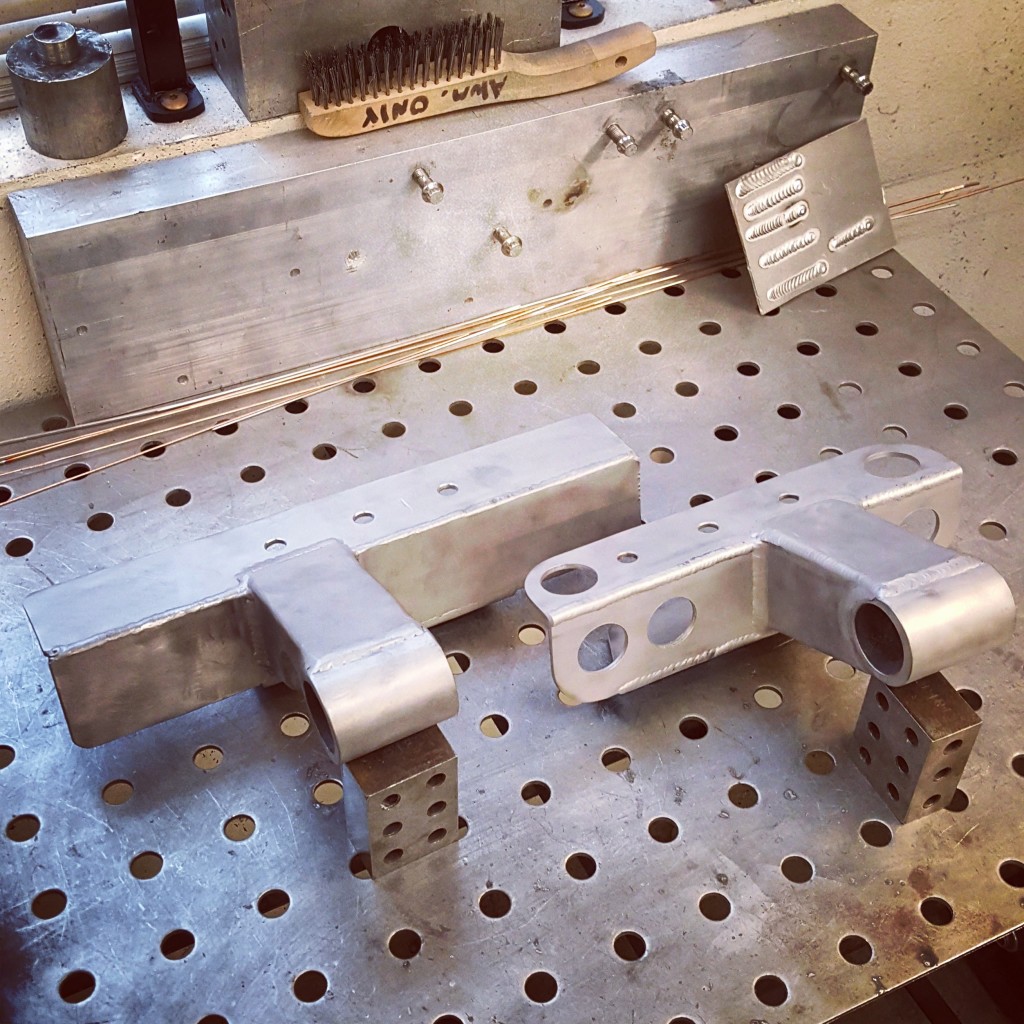

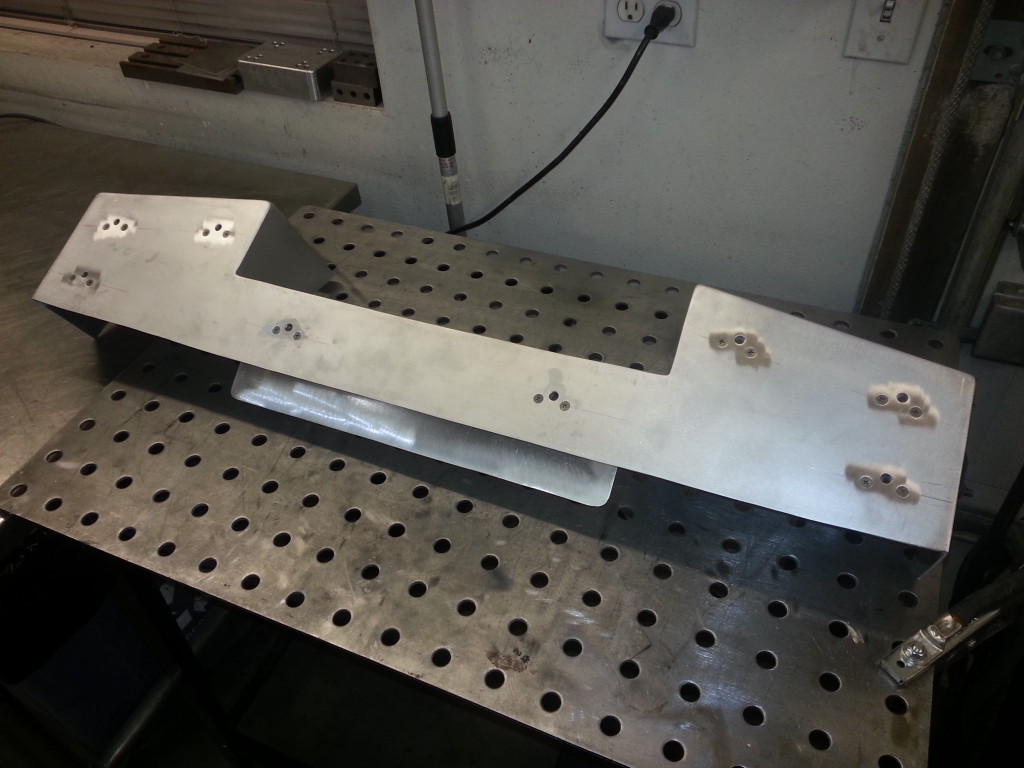

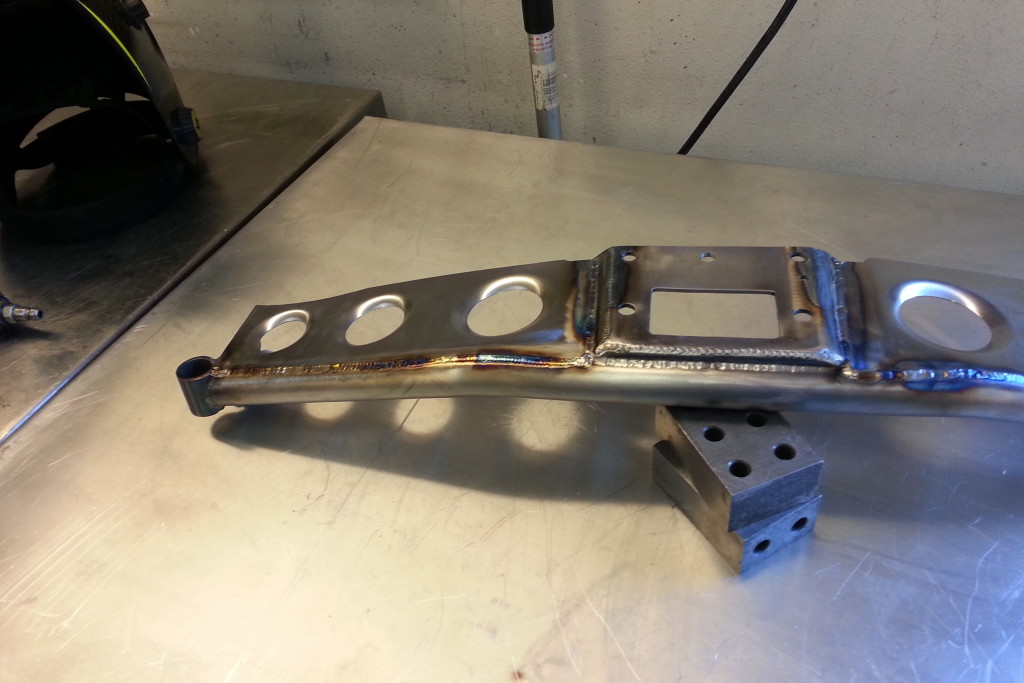

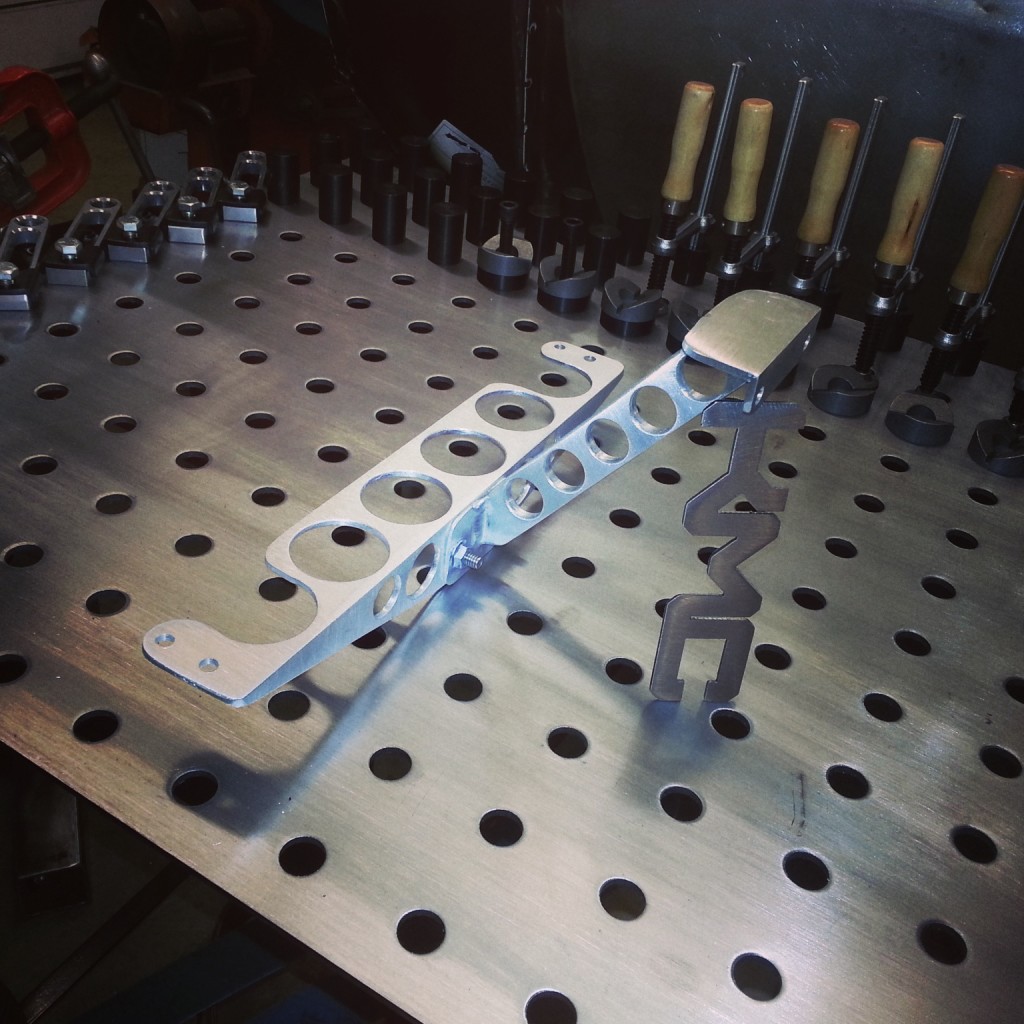

- The front rear diffuser bracket, 100% hand made by me, no cnc just a steady hand and a good tape measure

- cleaning up the custom engine mounts for a better appearance and reduced weight

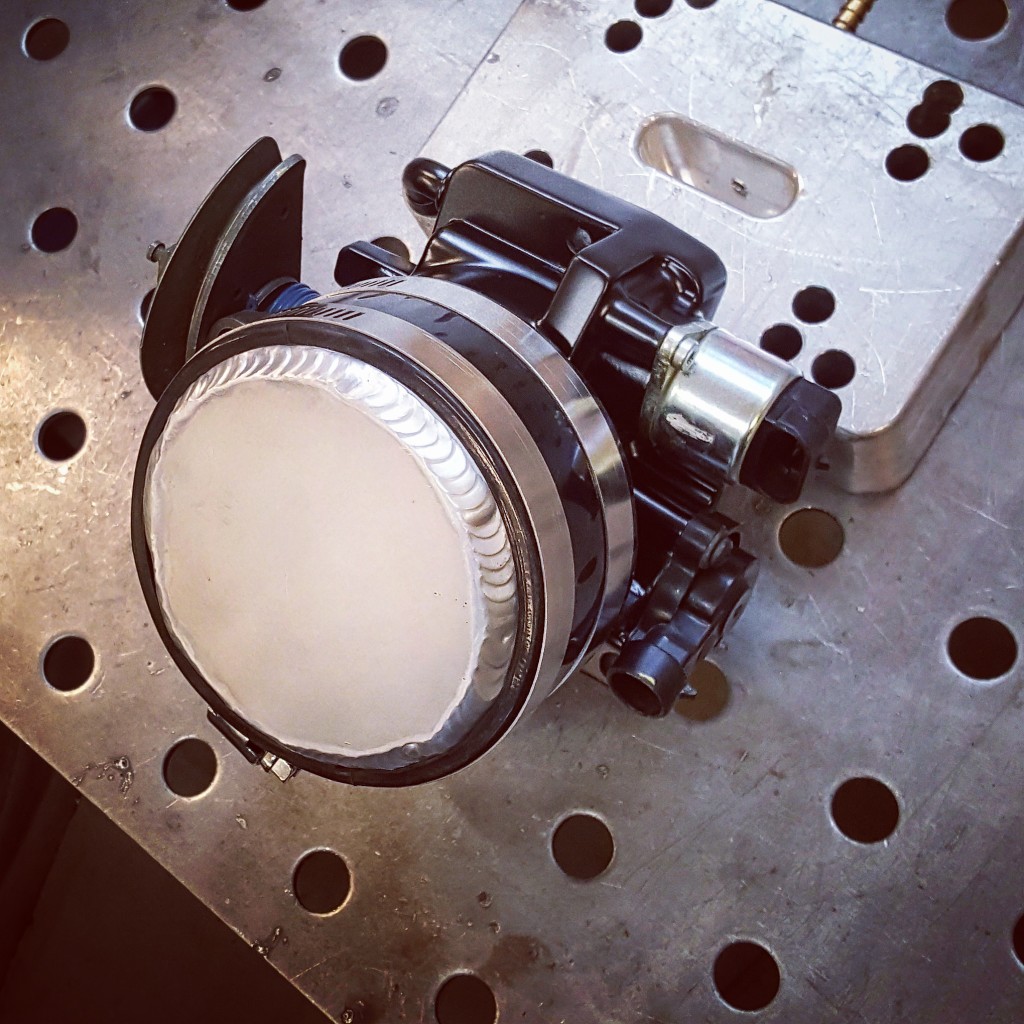

- a sweet throttle body plug I made to ease with reassembly, plus it just looks good.

- Saving some weight on thes engine mounts

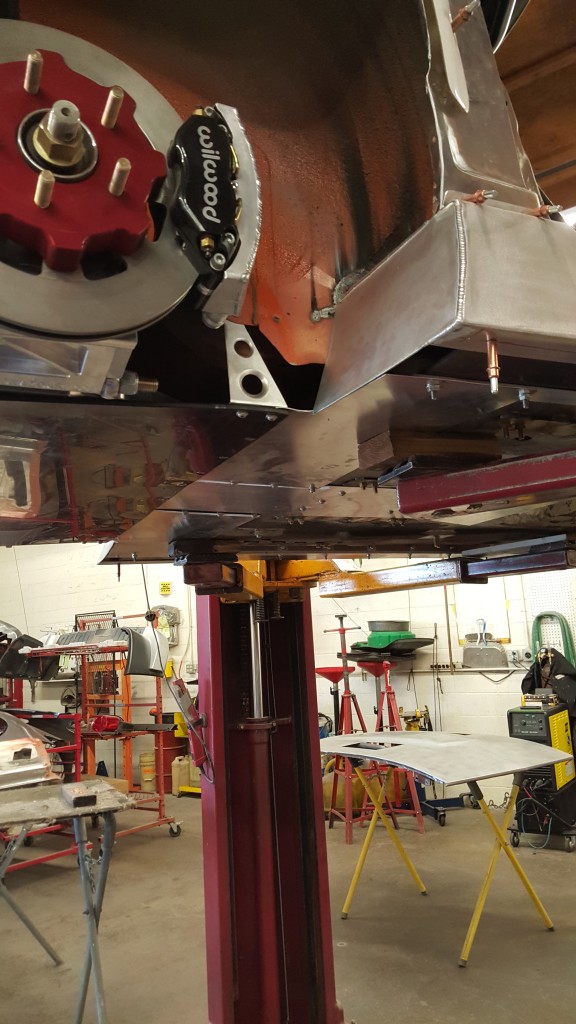

- Chassis jacking points built in to the bottom side of the main cage hoop tie ins, extremely strong!

- Bryan the painter after a job well done!

- A tunnel so slick I think we will leave it uncovered

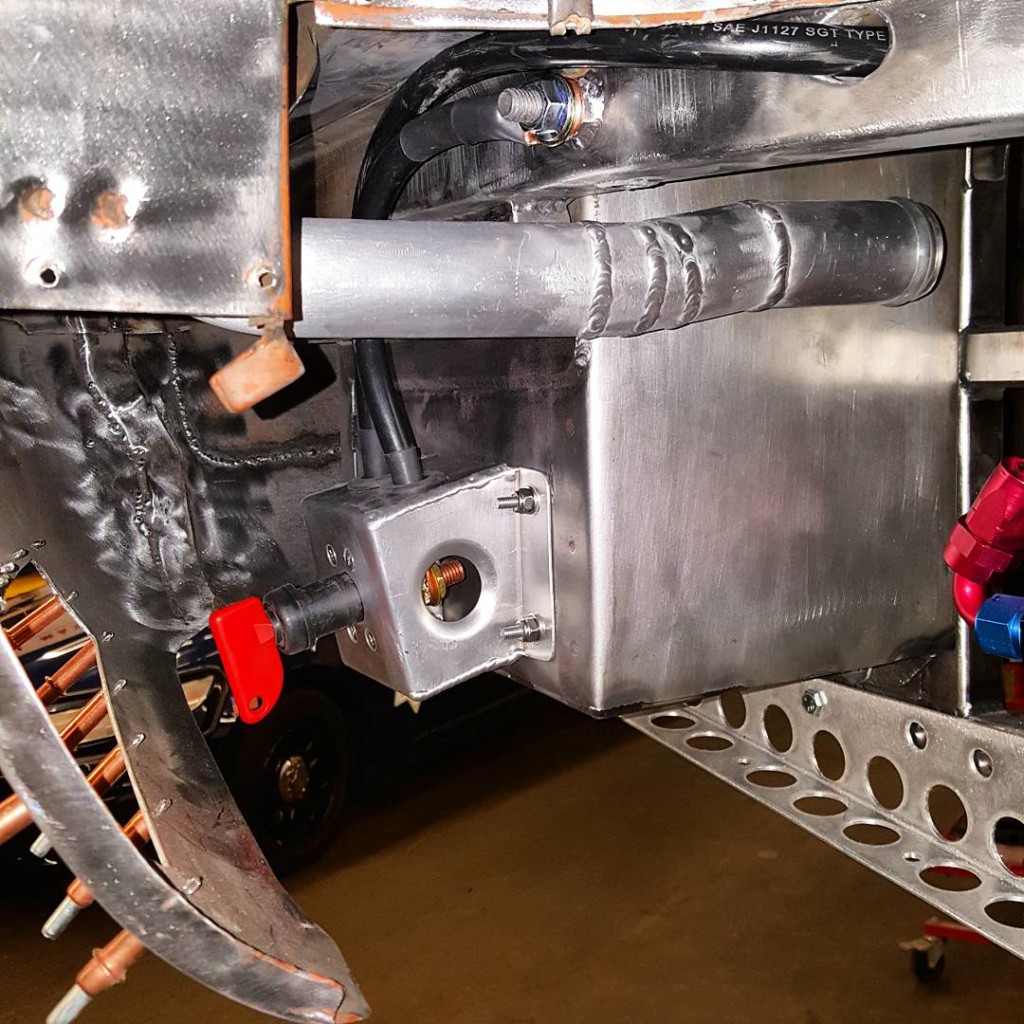

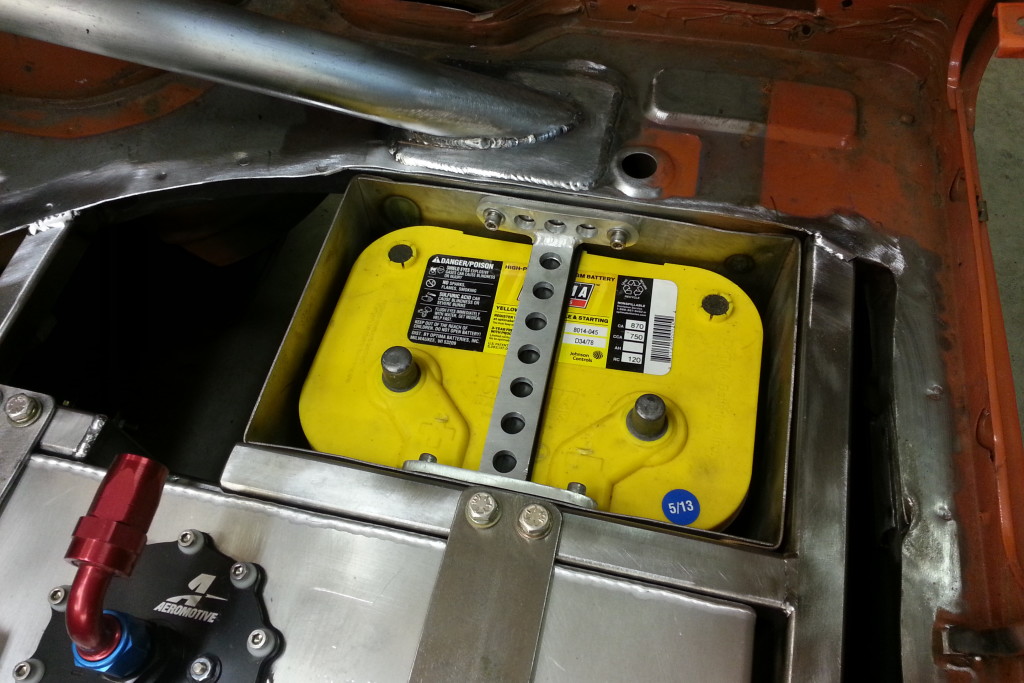

- a custom tig welded rear sub mount battery box

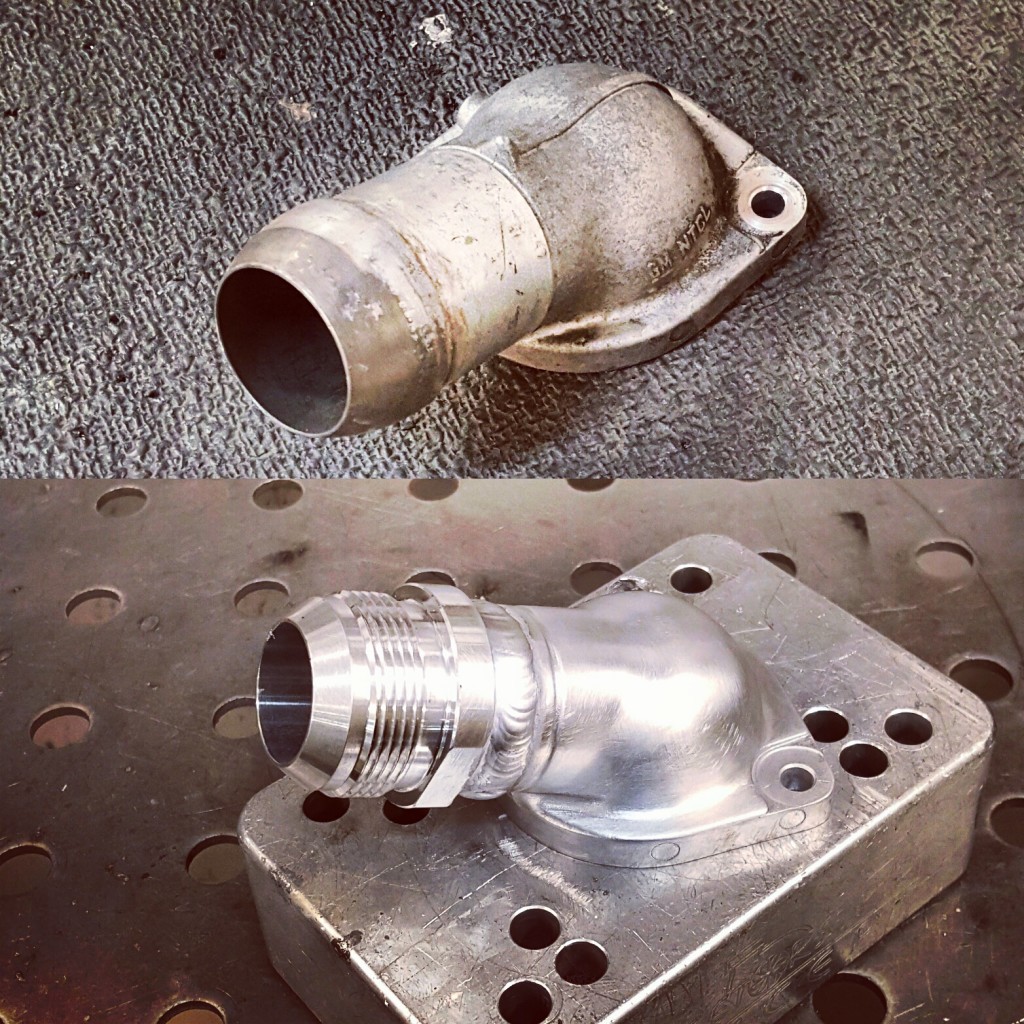

- The factory steam port into the throttle body before removal

- A nicely detailed and cleaned throttle body, what’s missing?

- the dirty motor before cleanup

- a few hours of hard scrubbing goes a long way

- I must combine these two

- Ah, much better. All the casting marks are cleaned up too for a truely custom part

- The last round of primer

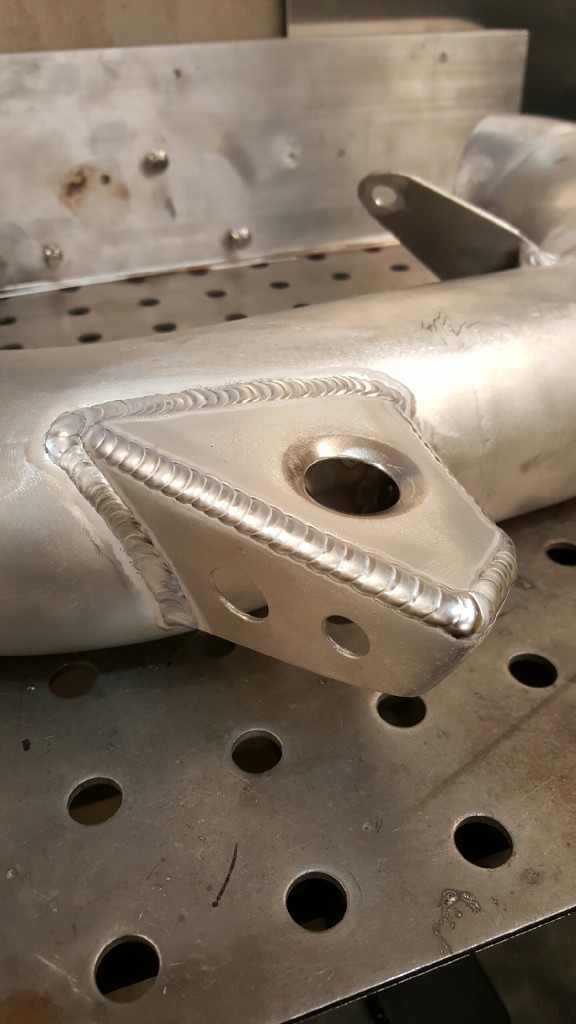

- Pretty alloy dimes on the coolant overflow tank

- Most of the custom handmade alloy parts awaiting final checks and the powdercoater

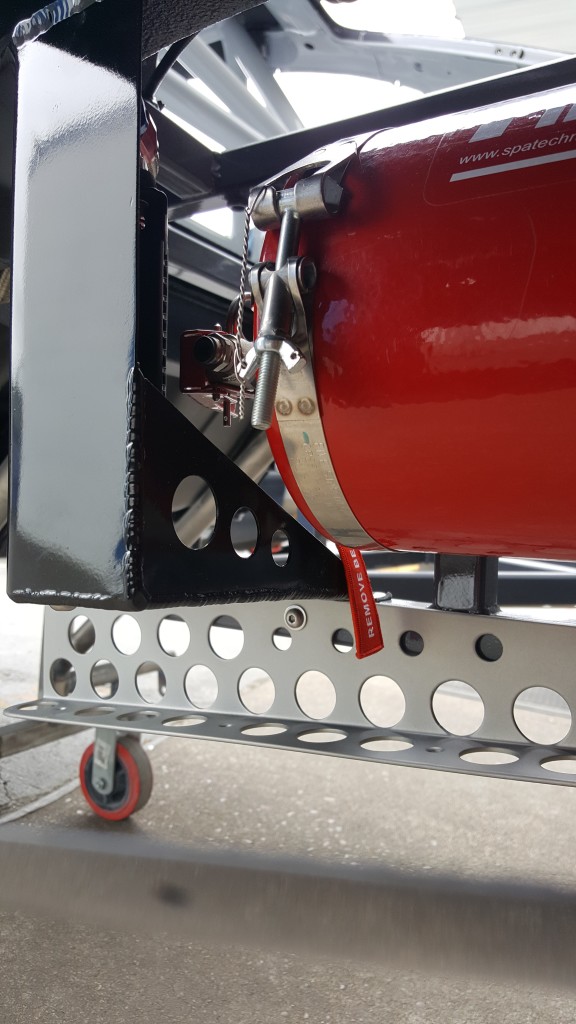

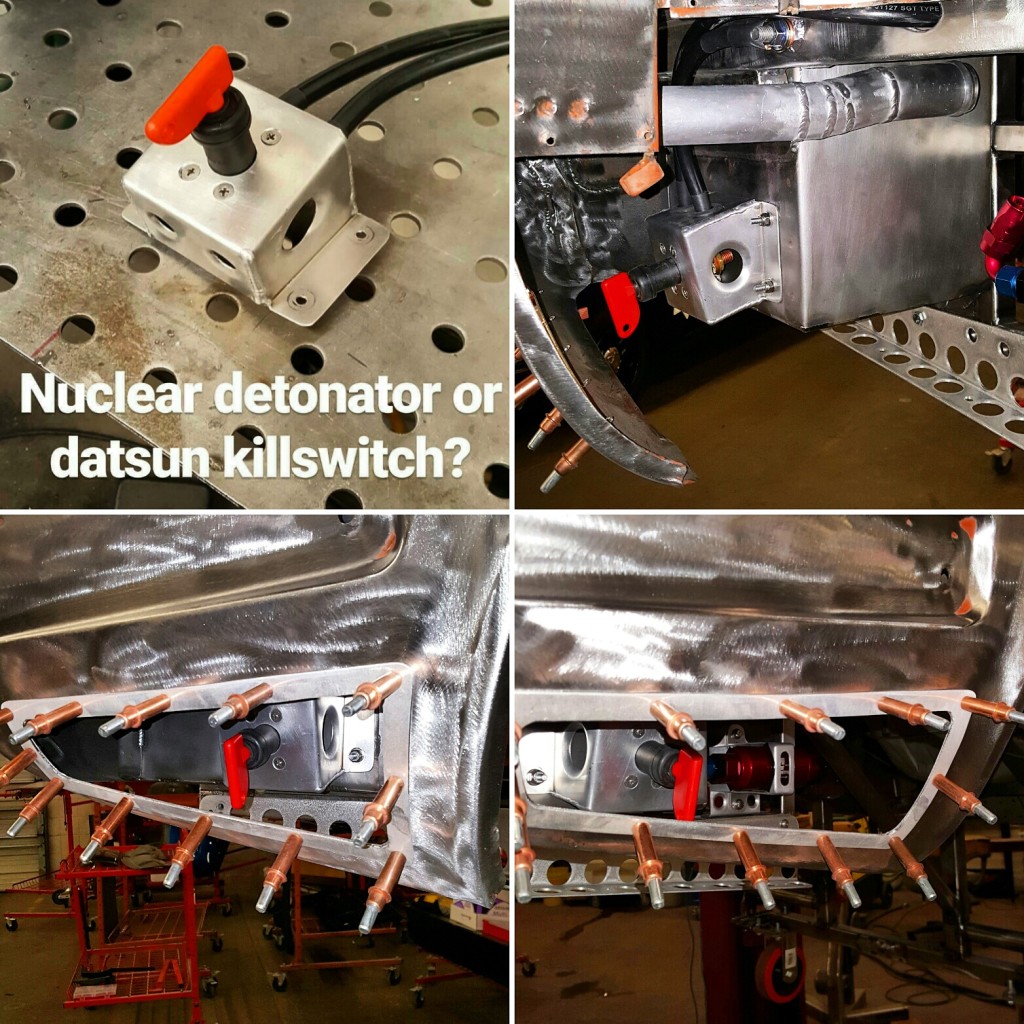

- I modified this SPA Techique fire suppression lever with a collet and pin so no accedental pulling can take place outside of a racing environment

- cool new parts to add to the list

- First round of primer blocking in the books

- final welding on the custom air intake support

- Finally, no more orange

- Quality gaps make the bodywork. I spent many hours welding and filing to perfection. All metal edges to boot.

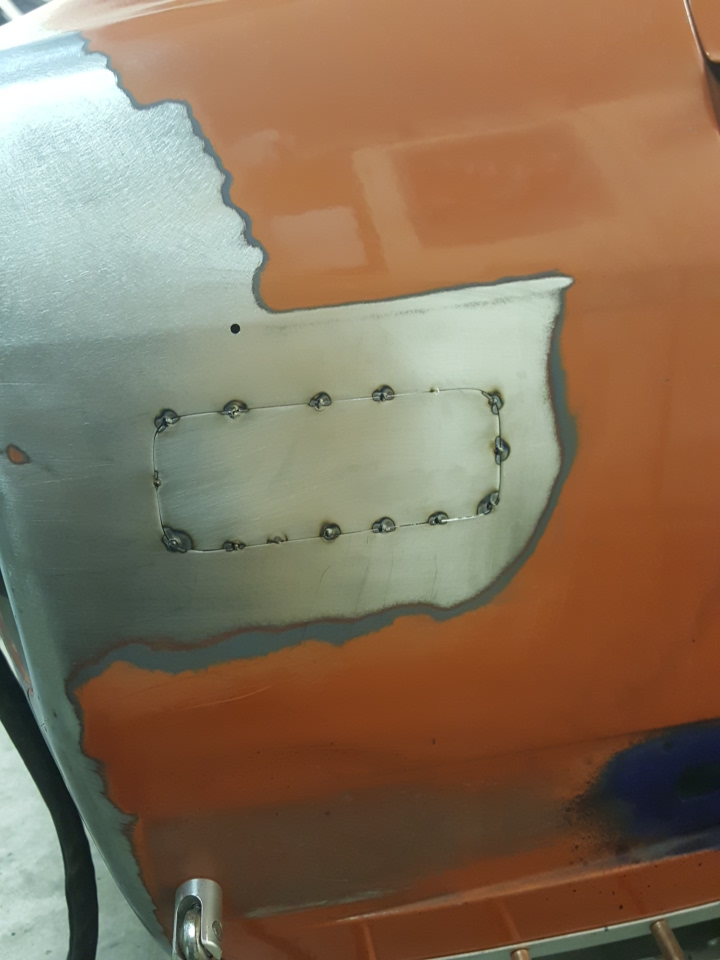

- The peep hole I cut to access the center deck spoiler mounts

- Adding stiffness to the deck lid spoiler mounting points. Nothing ever just bolts on

- Major reinforcement and armour to the unibody main rails

- stitch welded seams everywhere topside and underneath

- aditional seam welding for torsional strength

- is that hole factory? no, no it is not

- I love good cage work

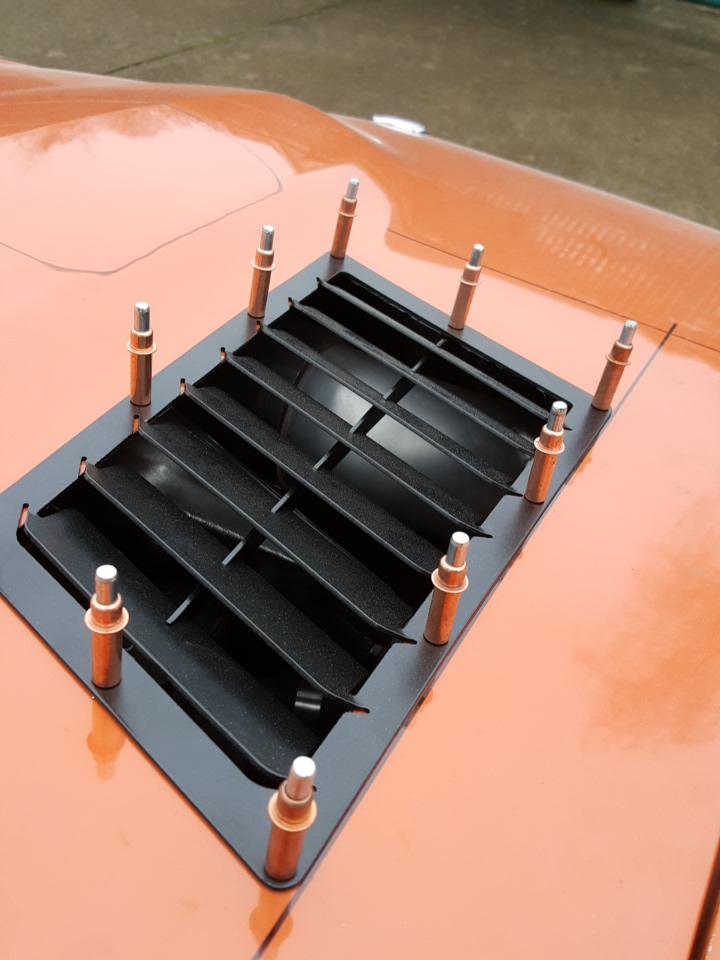

- Cleaning up the hood heat extractor vent openings

- a solid mount for the hydraulic slide lever

- The last hoorah before sealer

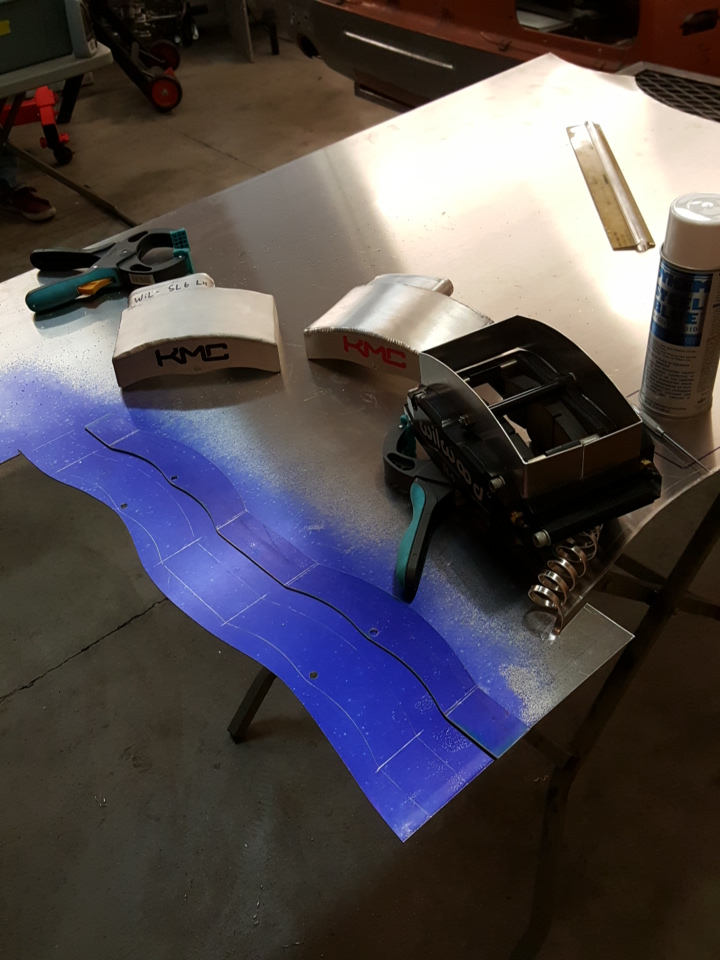

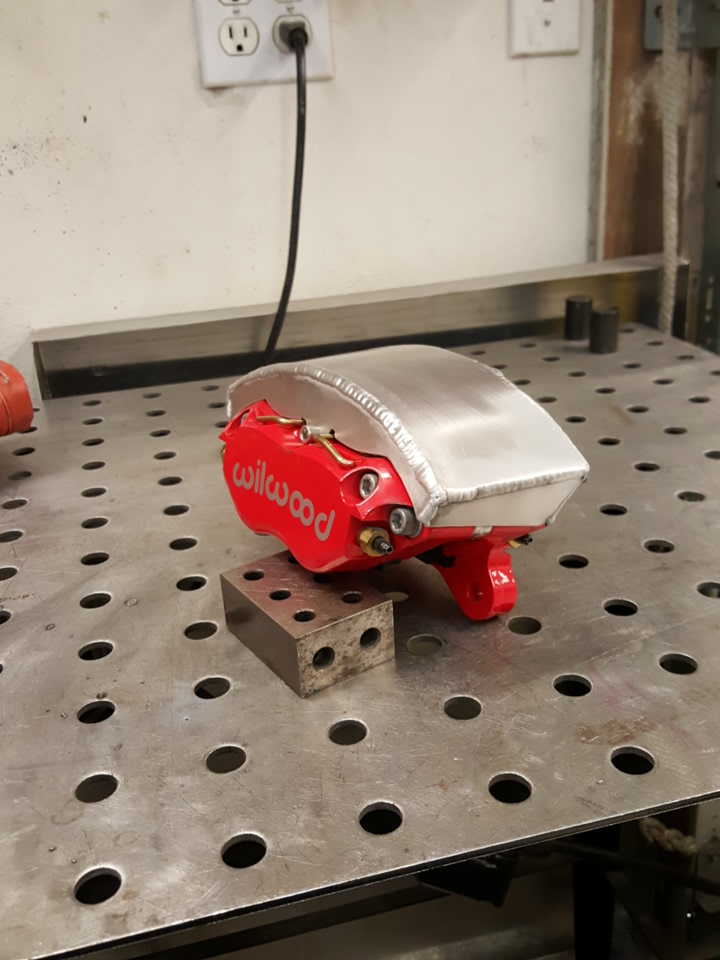

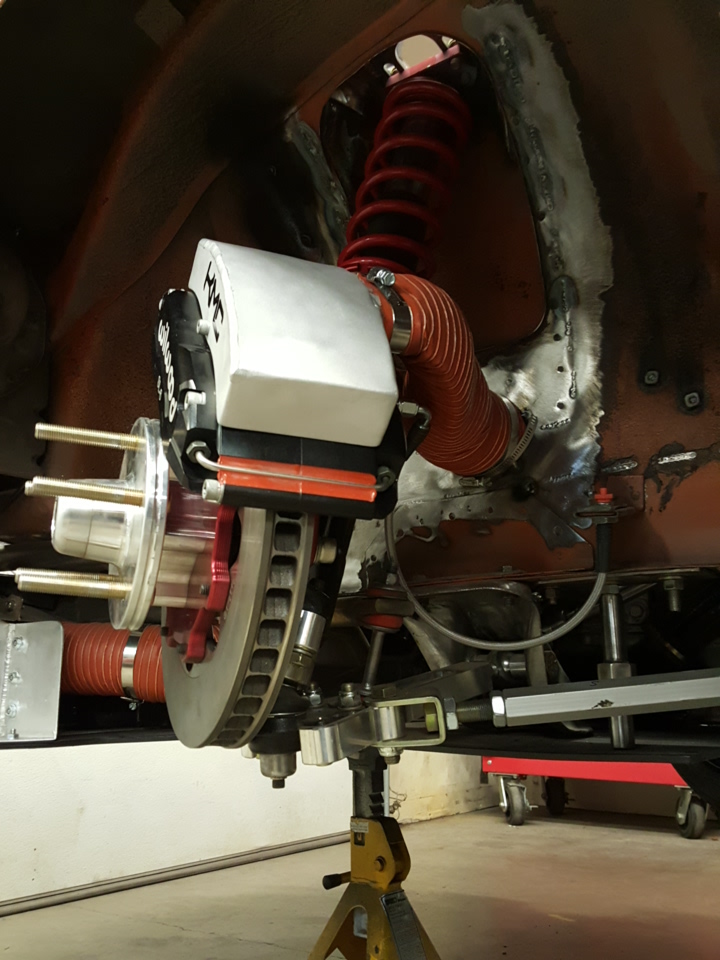

- Rear brake duct rocker clearancing and solid tow/jacking points

- nothing like cutting .750″ hardened steel by hand, but its for a good cause, protecting that beautiful exhaust

- reinforcing the rail exhaust cutouts

- fire suppression brackets added to the engine bay

- battery kill switch with a little flair

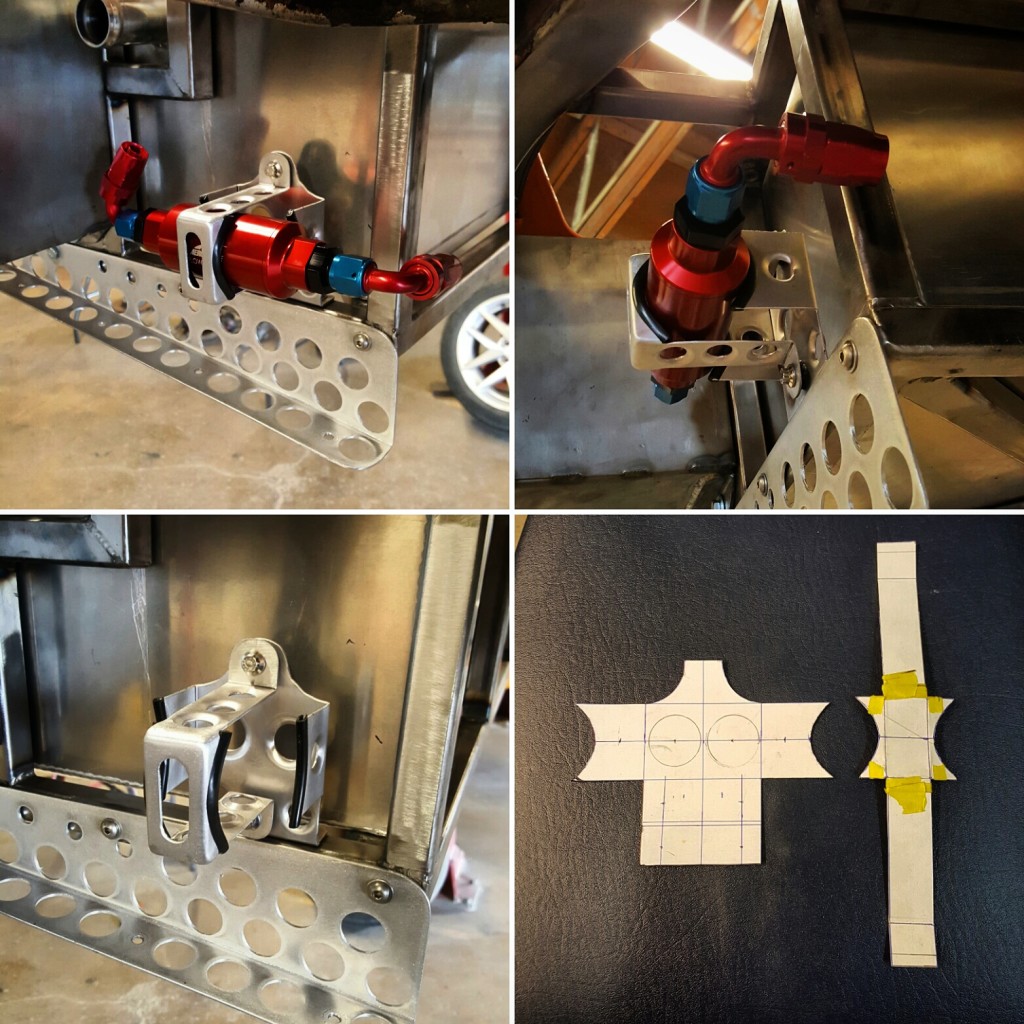

- The humped alloy pieces leave room and easy access to the fuel pump and check valve

- sometimes its best to walk away when a design isnt working. The abomination on the left is idea #1, need I say more?

- The steel riser gets welded to the chassis and flanged nuts welded to the backside for easy removal of the aluminum top piece. It began life as a flat sheet of 18 ga. the shrinker/stretcher did the rest

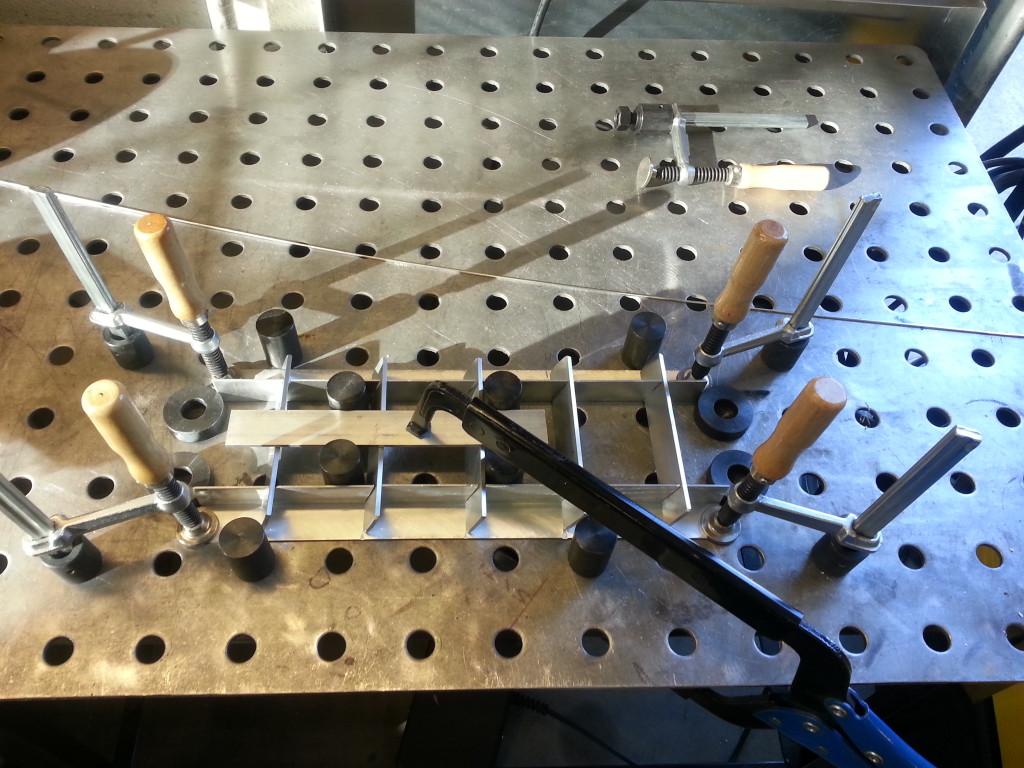

- making the tools to make the things. This was done before I purchased the electromagnetic break

- A handmade fuel filter bracket

- Hydraulic rear break lockup at the pull of a lever

- Out with the old, in with the cleaner new brake lines

- A whole lot of custom in one place

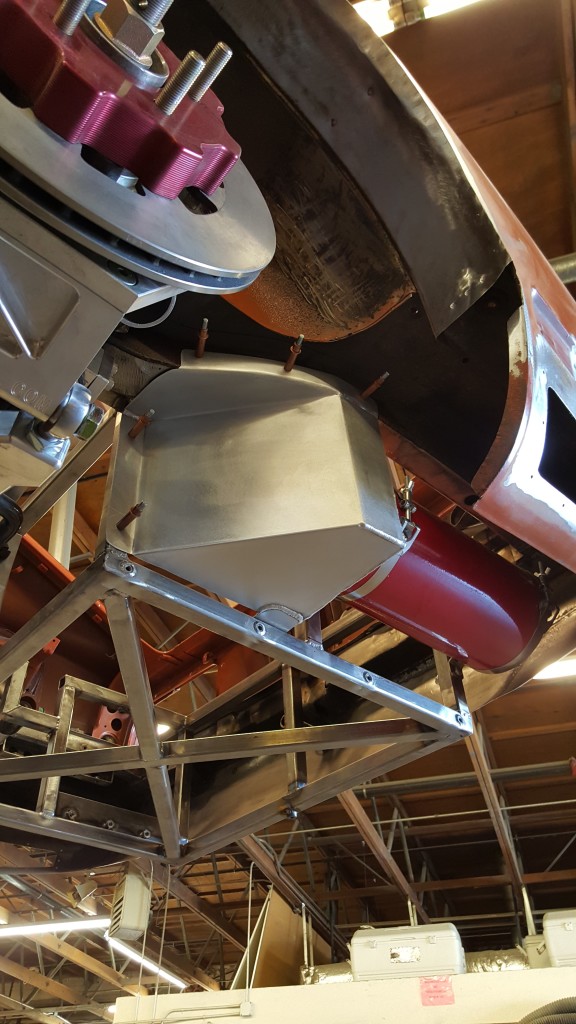

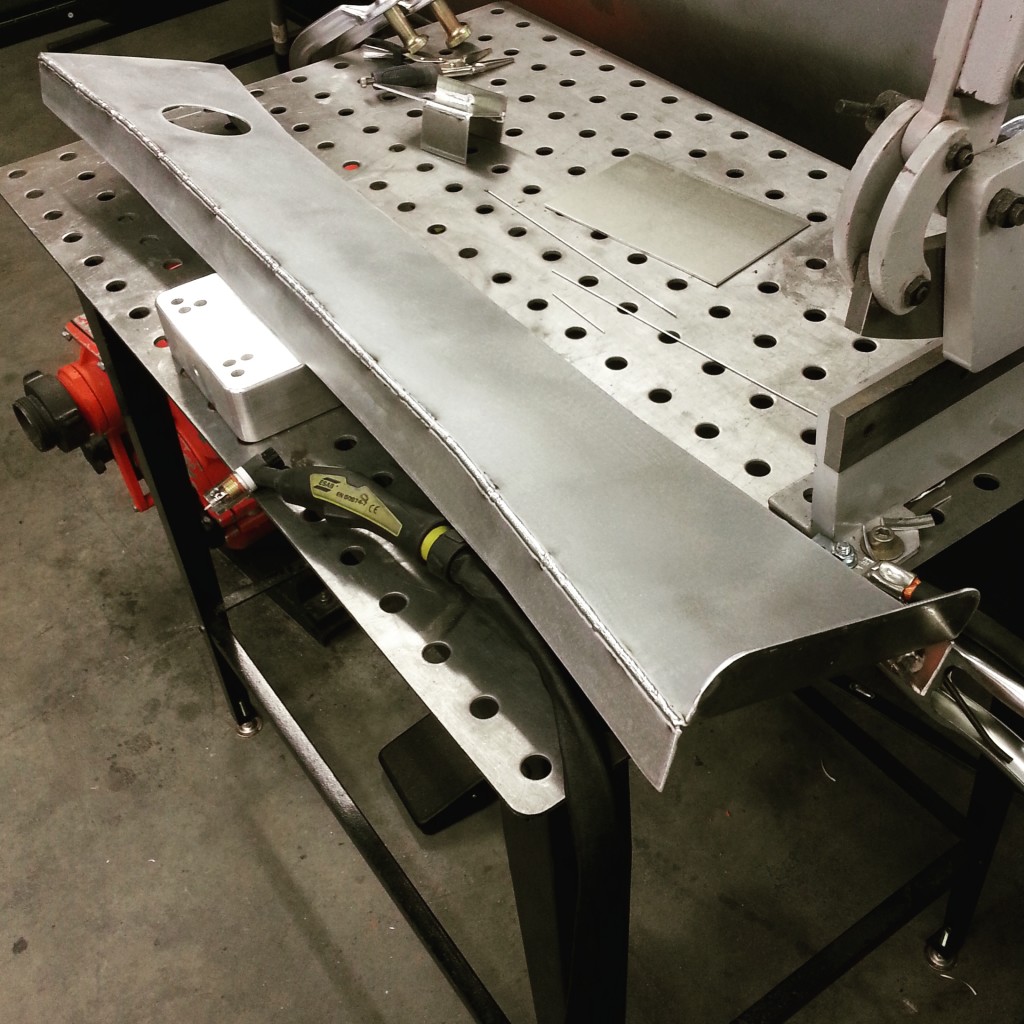

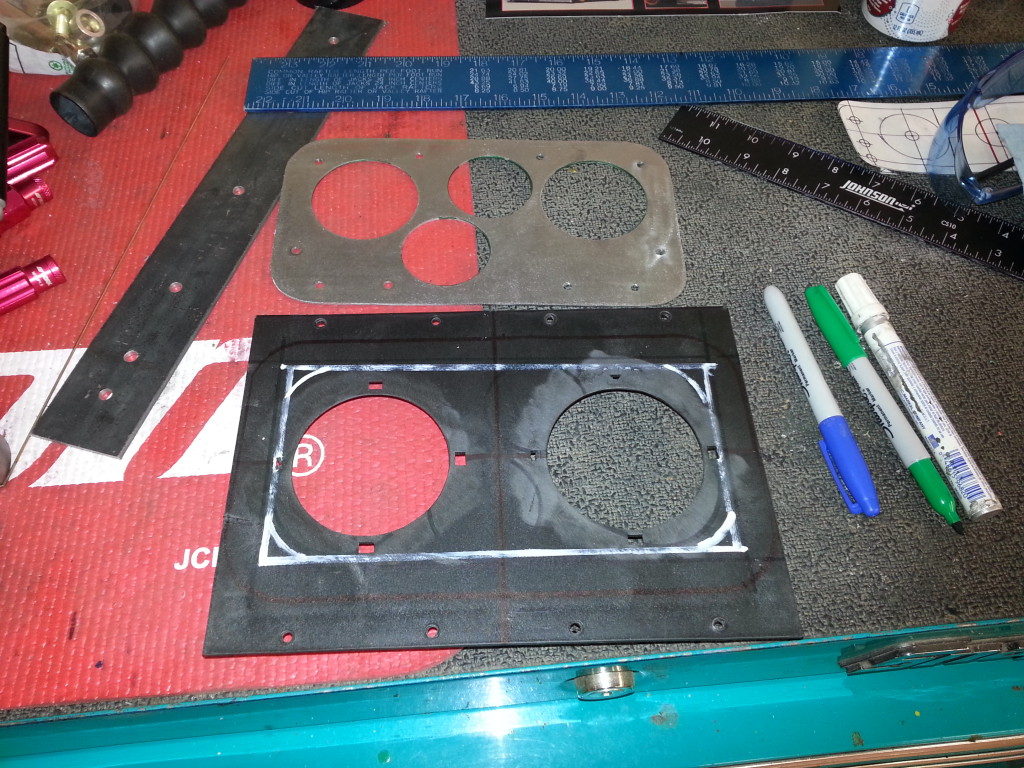

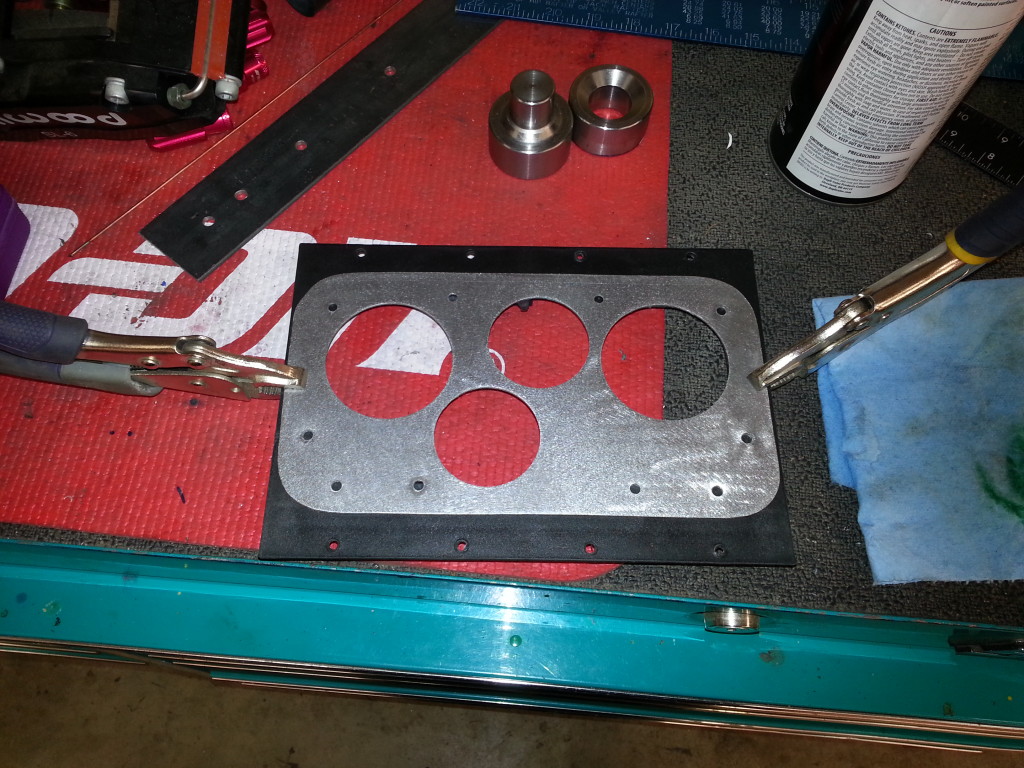

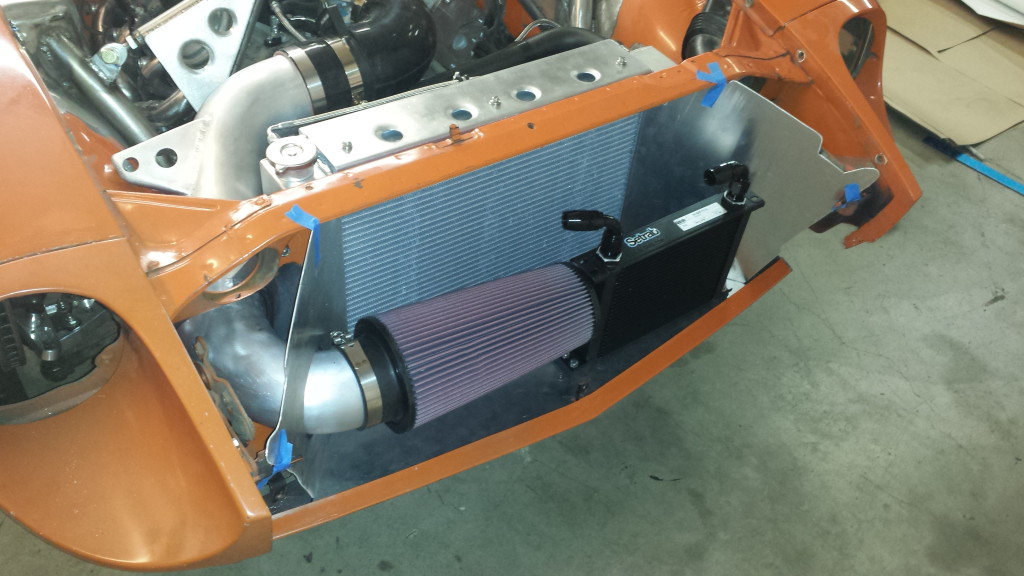

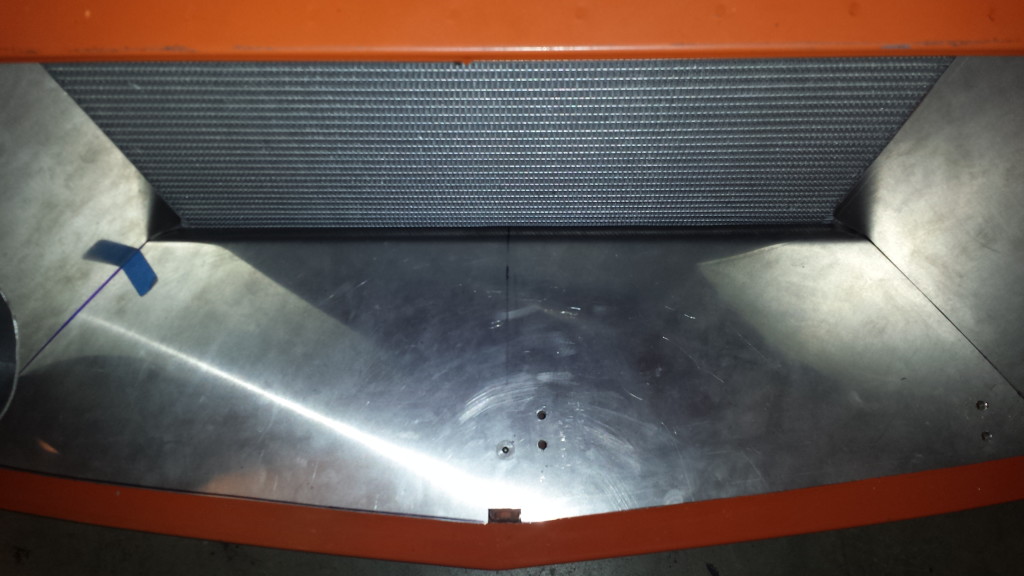

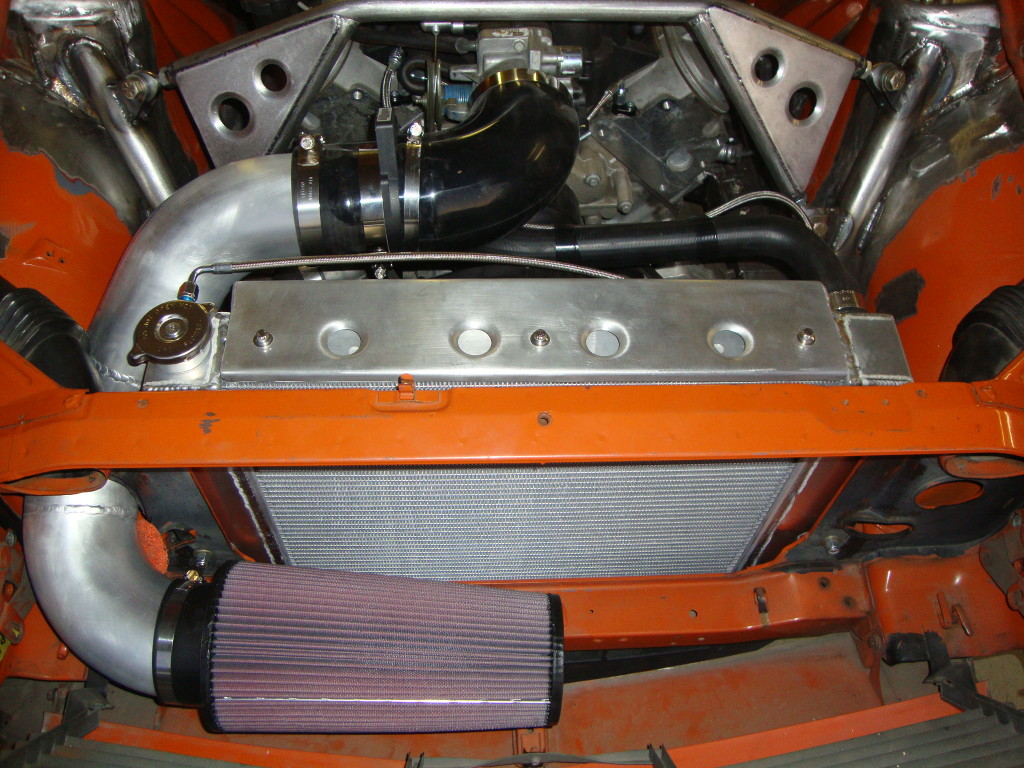

- Radiator air ducting done right. All light guage alloy and bolt on

- Inside the Brake master heat shield

- From the bottom, this will get coated with gold heat reflective material

- The prop. valve hides nicely under the master cylinder

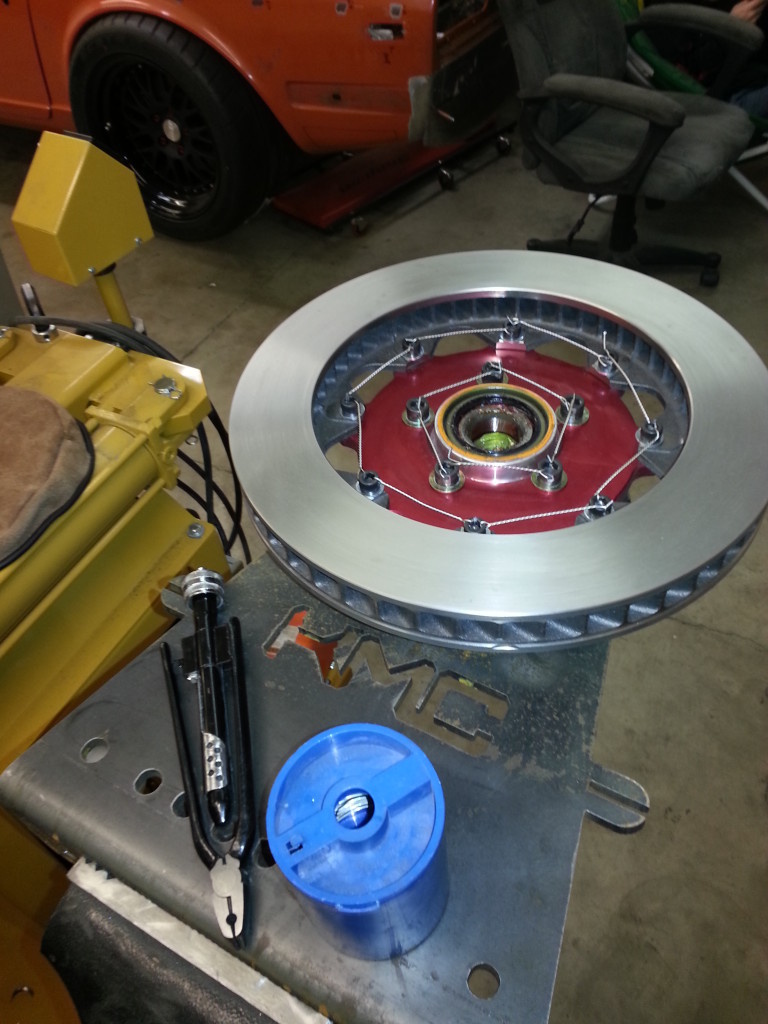

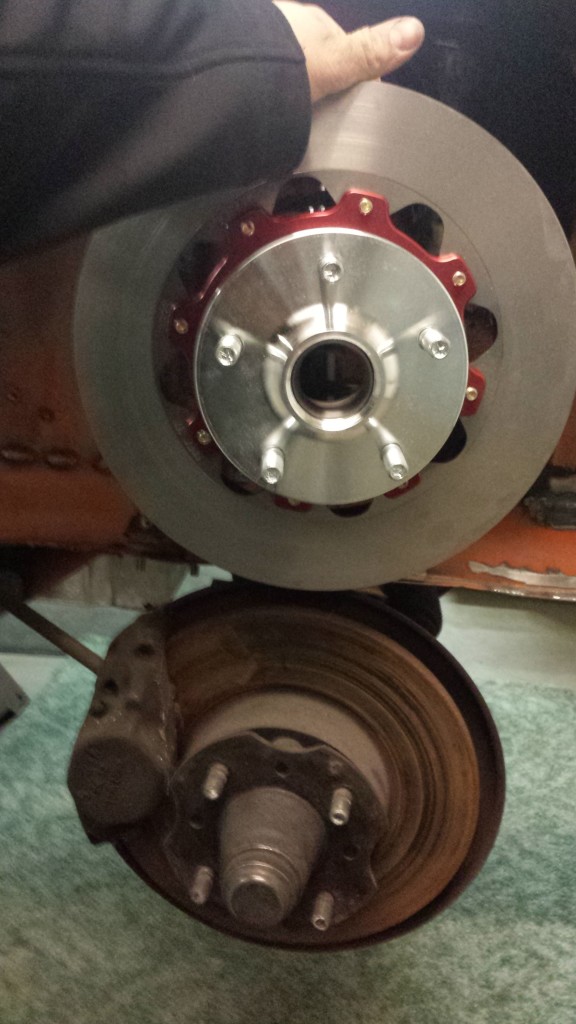

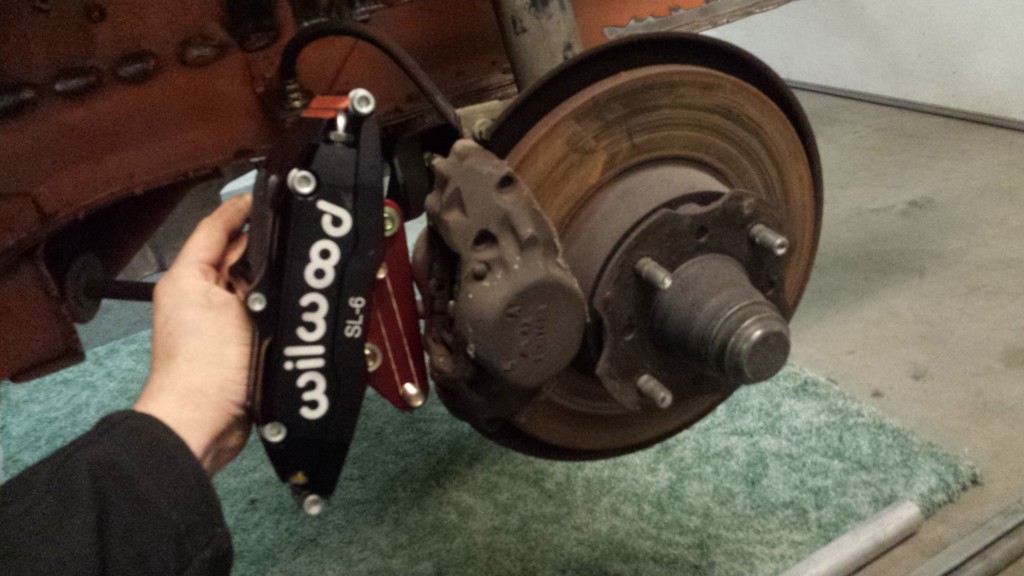

- Im a big fan of cool brakes

- Streamlining the factory systems once again

- From inside you cant tell Datsun didnt provide this column from the factory

- tig welding the flared hole gussets to the aprons.

- I really like this functional design. those towers aren’t going anywhere

- This shows how extreme the curvature is on these cage gussets

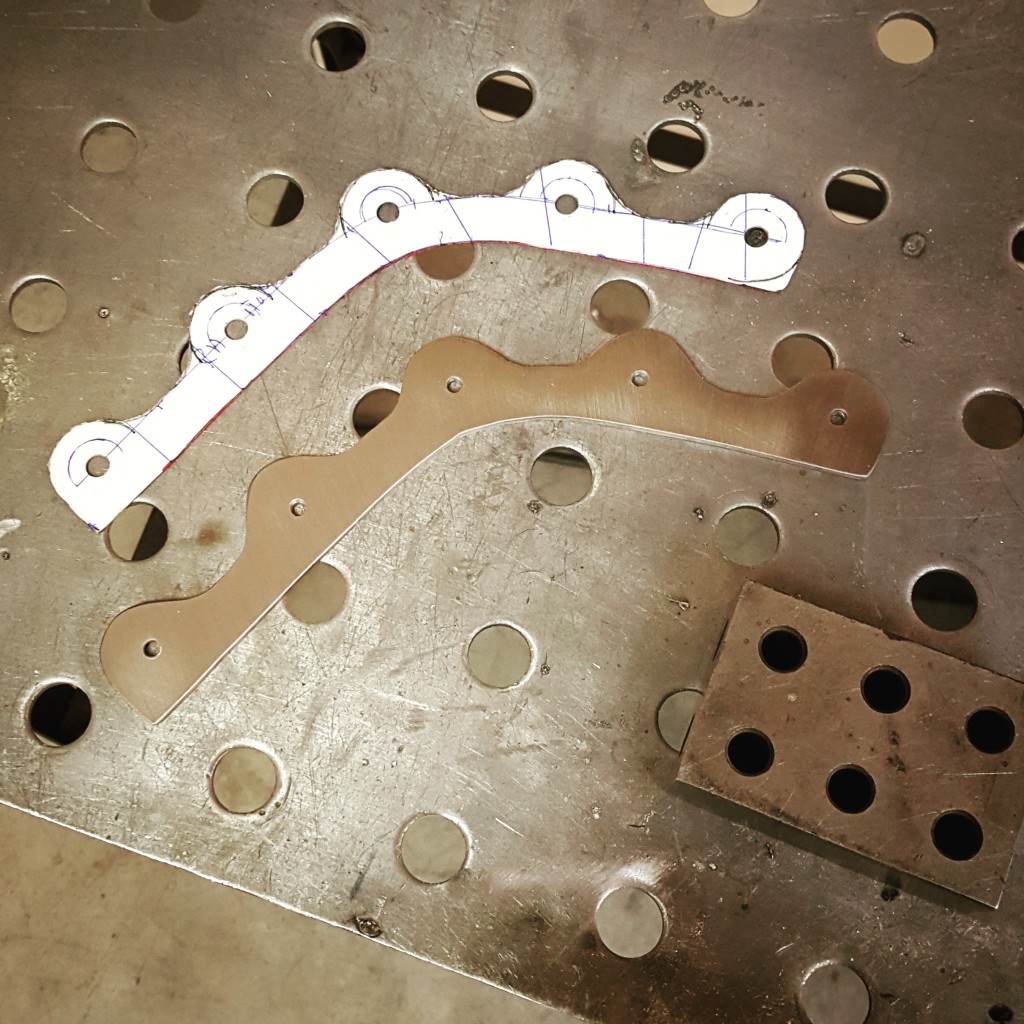

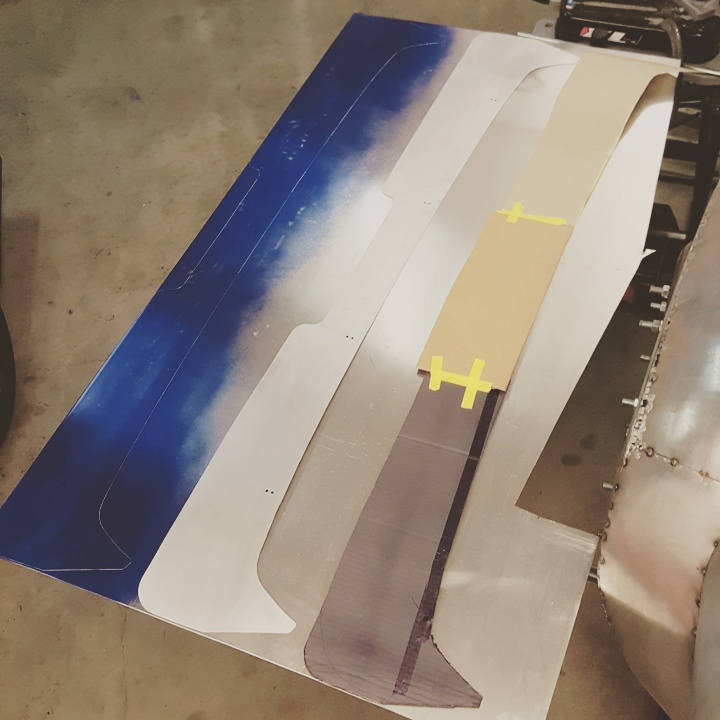

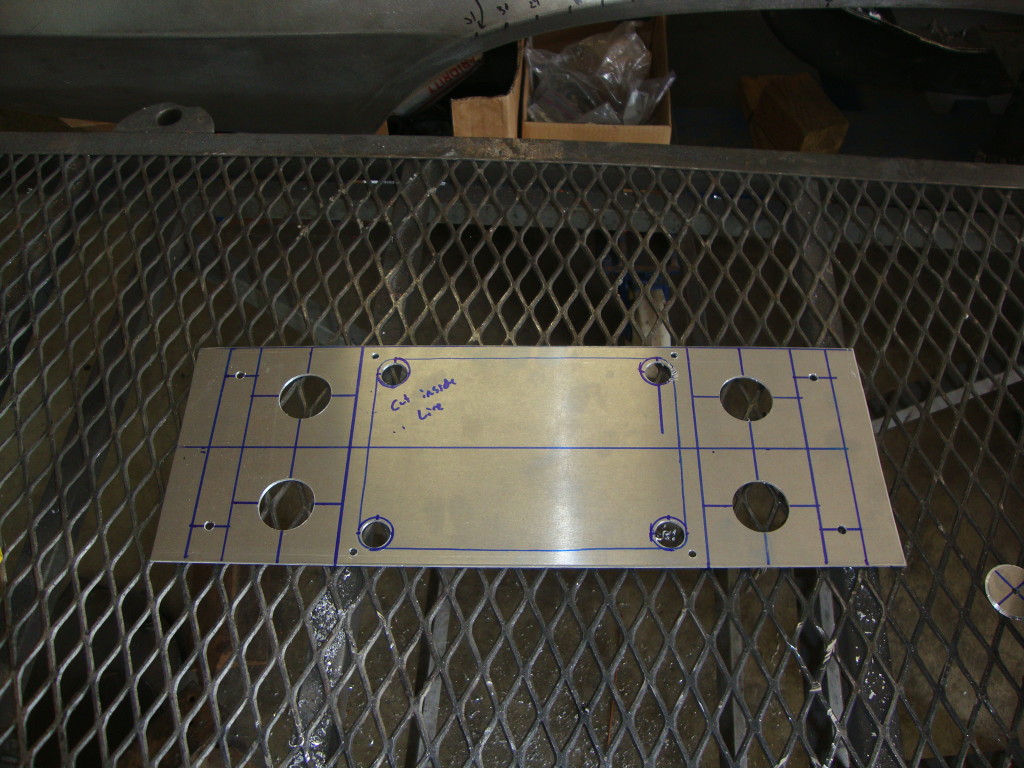

- From concept to reality, the poormans no CAD way

- strong

- It has come a long ways, looking this clean before any finish work too

- I fabbed this custom dolly to keep the Z mobile during the bodywork stage

- The rear custom dolly stand

- MY Z06 is scared and this car doesn’t have a motor

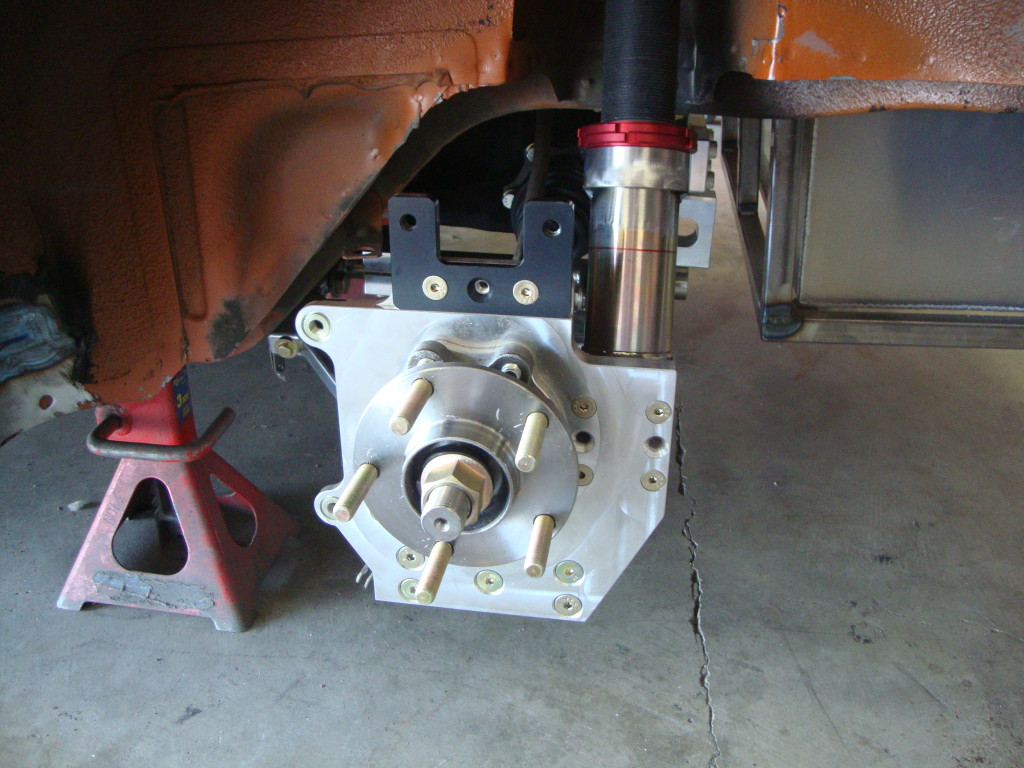

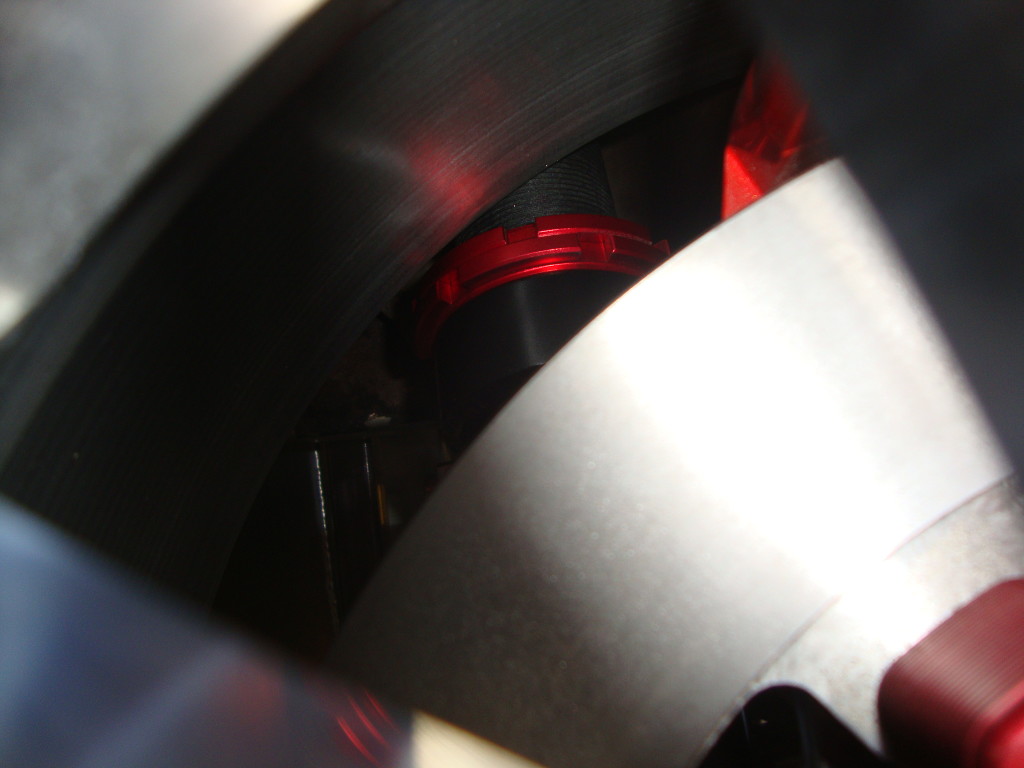

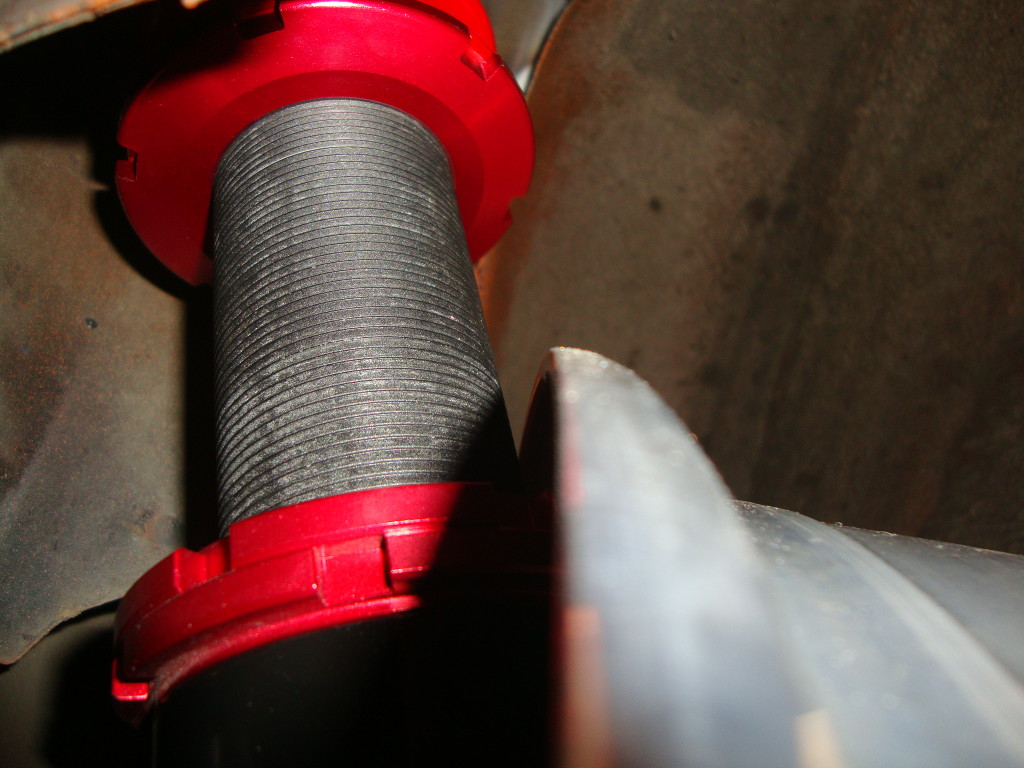

- AZC Billet goodness

- Chemically Stripping 40ish years of paint

- It has a horn, therefore it must be a “streetcar”

- Duct work

- Keeping all that air directed where it should go for better cooling and aerodynamics

- A shield to keep tire debis off the fire tank

- This cover protects the fire bottle and directs turbulant air off the tire out the quarter panel vent, win win.

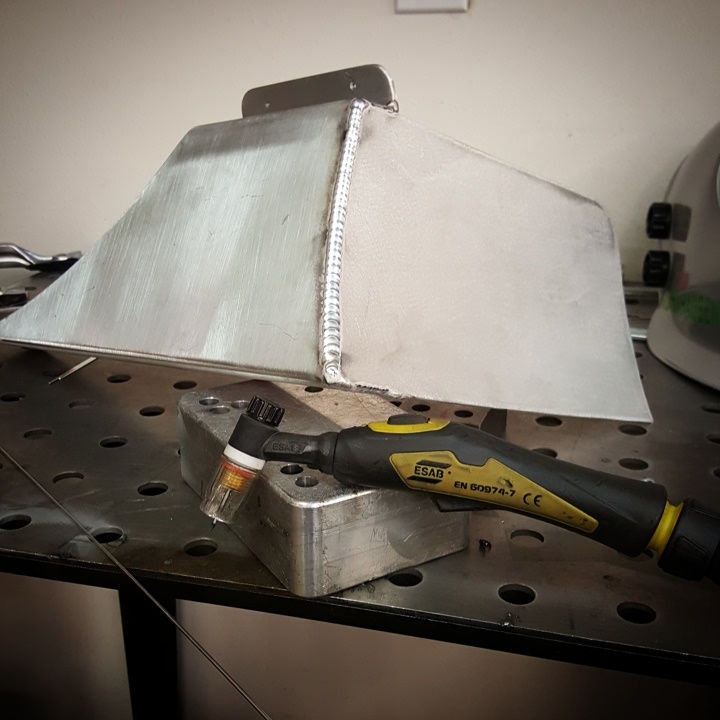

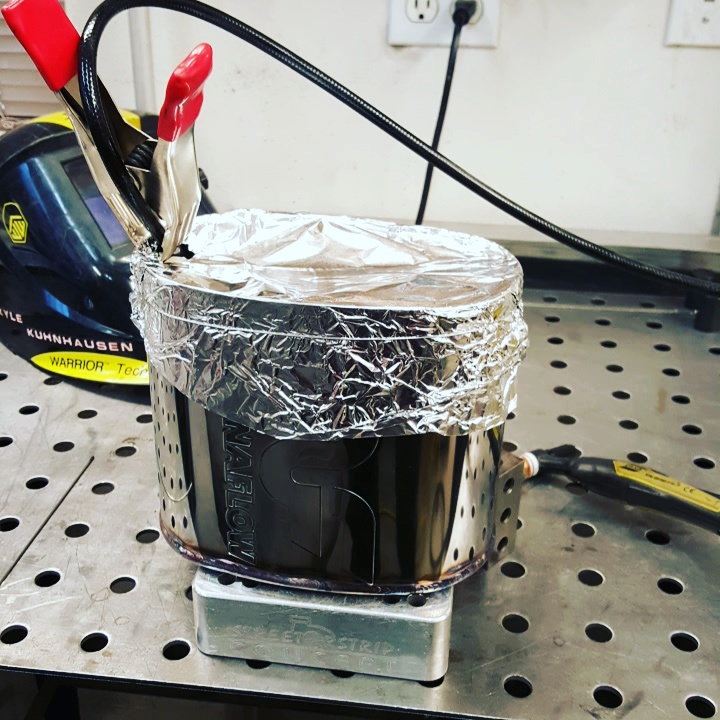

- Keeping the ultra thin guage alloy cool while welding

- The hdpe rear diffuser

- aluminum bellypan work keeps the air headed where it should

- Triming the main duct for integrated radar detection

- What’s that, don’t worry about it…

- I think she’s smiling

- Radar refractors hidden in the grill

- Dissasembly taking place

- A minor upgrade ahead of the core support

- form meets function

- DAMN, i mean dam…

- Front splitter

- the x-pipe sits in front of the oil pan sump

- pre-rear aerodynamics

- Leaving the fab shop en route to body and paint

- every angle leaves you wanting more

- beauty

- Hand cut 14 ga. brackets

- solid mounts to the body for the winglets

- Pitch adjustable rear spoiler

- rear brake duct detail

- I see you, hidden backup camera/ rearview in the dash

- Moving the filler neck from the top to the side

- air extraction alloy beauty rings

- muscular hips

- How all my bracketry starts

- Fuel tank and differential vents

- “KMC” you know the rest

- A builders perspective, each part is used to create the bigger picture

- Tidy Tig welding with my trusty ESAB machine

- Rear brake duct

- Doing things the old fashioned way, always a pleasure

- Ugly bumper bracket

- No more bumper in the rear

- shaving side markers

- making this unsymetrical recess symetrical

- The symetrical inset really sets off the rear end

- a tight fitup for the tig welding

- She has come a long way, lots left to go though

- The progression of templates

- Ground clearance leaving the driveway, no scrapes!

- Hood air vents give you a taste of whats under